Introduction

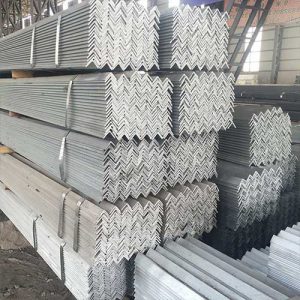

Steel angles are structural components made from steel and formed into an L-shape, with two legs at a 90-degree angle. They are used extensively in construction and manufacturing for their ability to provide both strength and flexibility in structural applications. These components are particularly important in metal framing, providing support, reinforcement, and stability.

In this blog, we will explore why steel angles are essential for metal framing and support. We will also look at their various applications, types, and the key factors to consider when selecting steel angles for your project.

What Are Steel Angles?

Steel angles are L-shaped steel pieces that have equal or unequal legs, depending on the application. They are commonly used in construction, engineering, and fabrication to support beams, columns, and other structural elements. Steel angles come in different sizes, thicknesses, and grades, making them highly customizable for a wide range of projects.

The L-shape provides excellent strength and resistance to bending, allowing steel angles to handle substantial loads. This makes them particularly useful for framing, bracing, and reinforcing metal structures.

Why Steel Angles Are Crucial in Metal Framing and Support

Versatility in Structural Applications

One of the primary reasons steel angles are so crucial in metal framing is their versatility. Steel angles can be used in various applications, from reinforcing beams and columns to creating frameworks for shelving, fencing, and even large-scale industrial structures. Their flexibility in use means they can be applied in different types of construction, including residential, commercial, and industrial projects.

Steel angles are often used to:

- Provide lateral support for beams and columns.

- Reinforce corners and joints in structural frameworks.

- Create shelving and supports in warehouses and factories.

- Form the basis for trusses, bridges, and towers.

This versatility extends to both small-scale and large-scale projects, making steel angles an indispensable component in modern construction.

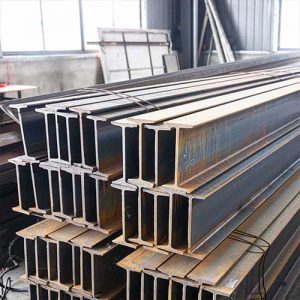

Enhanced Strength and Durability

Steel is well known for its incredible strength and durability, and steel angles are no exception. The L-shaped design allows steel angles to support significant weight without bending or buckling, making them ideal for load-bearing applications. In metal framing, steel angles are often used to create strong, stable structures that can withstand heavy loads, vibrations, and other stresses.

The inherent strength of steel angles also makes them highly durable, capable of resisting wear, corrosion, and environmental damage over time. This makes steel angles suitable for use in both indoor and outdoor applications, including:

- Structural frames for buildings.

- Outdoor fencing and railings.

- Industrial shelving and storage systems.

- Agricultural equipment and infrastructure.

Their durability means that steel angles provide long-lasting support and reinforcement for structures, reducing the need for repairs or replacements over time.

Cost-Effectiveness and Availability

Another reason steel angles are so popular in construction and metal framing is their cost-effectiveness. Steel is a relatively inexpensive material compared to other structural materials like aluminum or composite metals, and steel angles are widely available in a range of sizes and grades. This makes them a cost-efficient choice for both large and small construction projects.

Steel angles also offer excellent value for money due to their long lifespan and low maintenance requirements. Once installed, they require little upkeep, making them a low-cost solution for supporting and reinforcing metal structures.

The combination of affordability, strength, and availability makes steel angles a go-to choice for metal framing and support in various industries, including construction, manufacturing, and engineering.

Types of Steel Angles and Their Applications

Steel angles come in different varieties depending on their shape, size, and material properties. Here are the main types of steel angles and their typical applications:

Equal Steel Angles

Equal steel angles have legs of the same length, forming a perfect right angle. They are commonly used in applications where the load is distributed evenly along both legs. Equal steel angles are often used in:

- Reinforcing beams and columns.

- Supporting horizontal and vertical loads.

- Providing framework for bridges, towers, and buildings.

Unequal Steel Angles

Unequal steel angles have one leg longer than the other, which allows them to provide more support in one direction. This makes them ideal for applications where the load is uneven or concentrated on one side. Unequal steel angles are frequently used in:

- Bracing and reinforcing frames.

- Supporting roofs and floors.

- Providing additional strength in corner joints.

Galvanized Steel Angles

Galvanized steel angles are coated with a layer of zinc to protect against corrosion and rust. They are ideal for outdoor applications or environments where the steel will be exposed to moisture and chemicals. Common uses for galvanized steel angles include:

- Fencing and railing for outdoor structures.

- Support beams for outdoor sheds, barns, and greenhouses.

- Structural frameworks in industrial and coastal areas.

Stainless Steel Angles

Stainless steel angles are made from corrosion-resistant stainless steel, making them suitable for environments where hygiene and resistance to chemicals are essential. These angles are often used in:

- Food processing and pharmaceutical industries.

- Water treatment plants.

- Chemical storage and handling facilities.

The choice of steel angle type depends on the specific requirements of your project, including the load it needs to support, the environment, and the material properties needed for durability.

How to Choose the Right Steel Angle for Your Project

Choosing the right steel angle is critical to ensuring the structural integrity and performance of your project. Here’s a table to help you compare the different types of steel angles based on key characteristics:

| Type of Steel Angle | Key Features | Best Applications | Cost Range |

|---|---|---|---|

| Equal Steel Angle | Even load distribution, symmetrical legs | Beams, columns, trusses, and general framing | Low to Moderate |

| Unequal Steel Angle | Uneven load distribution, asymmetrical legs | Roof supports, corner reinforcements, bracing | Moderate |

| Galvanized Steel Angle | Rust and corrosion-resistant | Outdoor applications, fencing, and exposed structures | Moderate to High |

| Stainless Steel Angle | Highly corrosion-resistant, hygienic | Chemical, food processing, and water treatment facilities | High |

By considering factors such as load requirements, environmental conditions, and budget, you can choose the most suitable steel angle for your project.

Installation Tips for Steel Angles in Metal Framing

Proper installation is crucial for maximizing the effectiveness of steel angles in metal framing and support. Here are a few tips to ensure a successful installation:

Accurate Measurement and Cutting

Before installing steel angles, ensure that all measurements are precise to prevent misalignment or gaps in the structure. Cutting the steel angles to the correct size is essential to ensure a snug fit and optimal support.

Correct Fastening and Welding

When attaching steel angles to other structural elements, use appropriate fasteners, such as bolts or screws, that can handle the load. If welding is required, ensure that it is done by a professional to avoid weak joints or potential failure.

Check for Alignment and Level

After installation, check that the steel angles are aligned correctly and that the structure is level. Misaligned or improperly supported steel angles can compromise the entire structure and lead to potential damage or collapse.

Conclusion

Steel angles are a vital component in modern construction and engineering projects. Their strength, versatility, and durability make them ideal for a wide range of applications, from reinforcing beams and columns to supporting large industrial structures. Steel angles offer an affordable, long-lasting solution for metal framing and support, whether you’re working on a small DIY project or a large-scale commercial building.

By choosing the right type of steel angle and following proper installation practices, you can ensure that your structure is stable, secure, and capable of withstanding heavy loads and environmental challenges. Whether you’re looking for cost-effective equal steel angles or corrosion-resistant stainless steel angles, these components are essential to creating safe and durable metal frameworks.

FAQ

What is the difference between equal and unequal steel angles?

Equal steel angles have legs of the same length, making them ideal for symmetrical load-bearing applications. Unequal steel angles have one leg longer than the other, which makes them better suited for situations where the load is uneven or concentrated on one side.

Can steel angles be used outdoors?

Yes, steel angles can be used outdoors, especially if they are galvanized or made from stainless steel. Galvanized steel angles have a protective zinc coating that prevents rust and corrosion, making them ideal for outdoor use. Stainless steel angles offer even higher corrosion resistance, making them suitable for environments with harsh weather conditions or exposure to chemicals.

What sizes do steel angles come in?

Steel angles are available in a wide range of sizes, from small angles for light-duty applications to larger, heavy-duty angles for industrial projects. Sizes typically range from 20mm to over 200mm, with thicknesses varying based on the application.

How do I know what type of steel angle to use for my project?

Choosing the right steel angle depends on several factors, including the load-bearing requirements, environmental conditions, and budget. For example, if you need an angle for an outdoor structure, galvanized or stainless steel angles may be the best choice. If the load is uneven, an unequal steel angle would be more suitable.

Are steel angles easy to install?

Steel angles are relatively easy to install, especially with the right tools and equipment. Accurate measurement, proper cutting, and secure fastening are key to ensuring a successful installation. For more complex projects, it may be necessary to hire a professional for welding and alignment.