Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

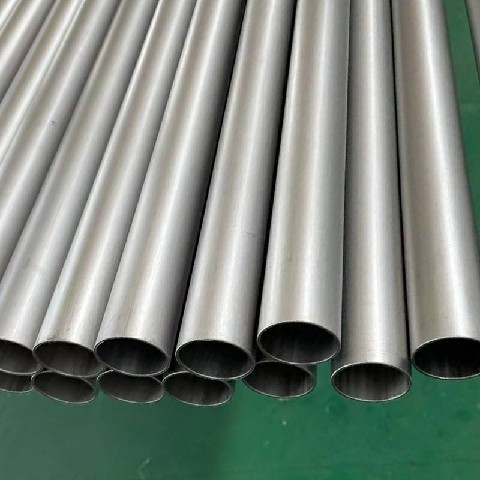

In the realm of industrial construction and engineering, the selection of materials is crucial for the success and longevity of any project. Among the various piping options available, alloy seamless pipes stand out for their exceptional strength, durability, and resistance to corrosion. These pipes are crafted from a single piece of metal, eliminating the potential weakness of welded seams, which can be a point of failure in traditional welded pipes. This comprehensive guide will explore the benefits of alloy seamless pipes, their applications, and why they are often the preferred choice for demanding projects.

Understanding Alloy Seamless Pipes

What are Alloy Seamless Pipes?

Alloy seamless pipes are tubular products made from alloy steel, which is steel that has been enhanced with other elements to improve its properties. These pipes are manufactured without any weld seam, providing a smooth inner surface and superior resistance to pressure and corrosion.

Key Features of Alloy Seamless Pipes

- High Strength: Alloy steel pipes offer greater strength and hardness compared to carbon steel pipes, making them suitable for high-pressure applications.

- Corrosion Resistance: The addition of alloying elements such as chromium, nickel, and molybdenum improves resistance to various forms of corrosion.

- Temperature Tolerance: These pipes can withstand extreme temperatures, from cryogenic to high heat, making them ideal for use in diverse environments.

- Dimensional Accuracy: Seamless construction ensures precise dimensions and consistent wall thickness, which is crucial for critical applications.

- Long Service Life: The durability and resistance to wear of alloy seamless pipes contribute to a longer service life compared to many other types of pipes.

Benefits of Alloy Seamless Pipes for Your Project

Enhanced Performance and Reliability

1. Pressure Resistance

The seamless nature of alloy seamless pipes allows them to withstand extremely high internal pressures without the risk of leaks or ruptures, ensuring the safety and reliability of your project.

2. Temperature Stability

Alloy seamless pipes can operate over a wide range of temperatures, making them suitable for applications where thermal cycling or high-temperature exposure is a concern.

3. Long-Term Durability

The robustness of alloy seamless pipes contributes to the longevity of your project, withstanding repeated use without significant degradation.

Cost-Effectiveness and Efficiency

1. Reduced Maintenance

Alloy seamless pipes require less maintenance than their welded counterparts, leading to cost savings over time.

2. Increased Efficiency

The seamless design of these pipes reduces the risk of leaks and failures, increasing the efficiency of fluid transfer and process control in your project.

3. Customization

Alloy seamless pipes can be customized to meet specific project requirements, including diameter, wall thickness, and material composition.

Applications of Alloy Seamless Pipes

Industrial and Process Piping

Alloy seamless pipes are used in process piping systems where high pressure, temperature extremes, and corrosion resistance are required.

Oil and Gas Industry

These pipes are essential in the oil and gas industry for drilling, transportation of hydrocarbons, and in refineries where they handle a variety of fluids at high pressures and temperatures.

Power Generation

In power plants, alloy seamless pipes are used for steam and water transportation, particularly in high-pressure boiler applications.

Chemical Processing

The pipes are used to handle aggressive chemicals and substances that require high pressure and temperature stability in the chemical processing industry.

Construction and Infrastructure

Alloy seamless pipes are used in construction for structural applications and as conduits for utilities, taking advantage of their strength and durability.

Alloy Seamless Pipe Specifications

| Specification | Description | Importance |

|---|---|---|

| Material | High-strength alloy steel | Determines the pipe’s strength and suitability for various environments |

| Seamless Construction | No weld seam for uniformity | Enhances pressure resistance and reduces the risk of leakage |

| Wall Thickness | Varies based on the pipe’s intended use | Affects the pipe’s ability to withstand pressure and corrosion |

| Outer Diameter | Ranges from small to large, depending on the application | Influences the flow rate and compatibility with fittings |

| Temperature Resistance | Ability to withstand high or low temperatures | Essential for applications with extreme thermal conditions |

| Pressure Rating | Indicates the maximum pressure the pipe can handle | Ensures safe operation under expected pressure conditions |

Case Studies and Real-World Applications

1. High-Rise Building Structures

Alloy seamless pipes are used in high-rise building structures for the vertical transportation of water and other utilities, providing structural support and reliability.

2. Offshore Oil Rigs

In offshore oil rigs, these pipes are critical for the safe and efficient transportation of oil and gas under extreme conditions.

3. Power Plant Boilers

Alloy seamless pipes are used in power plant boilers for steam generation, where they can handle high pressures and temperatures.

4. Chemical Plant Piping Systems

In chemical plants, these pipes are used to handle chemicals and substances that require high pressure and temperature stability.

5. Submarine Pipelines

Alloy seamless pipes are used for submarine pipelines due to their corrosion resistance and ability to withstand water pressure at great depths.

6. Automotive Exhaust Systems

Alloy seamless pipes are used in automotive exhaust systems for their high-temperature resistance and durability.

7. Aerospace Applications

In the aerospace industry, alloy seamless pipes are used for fuel and hydraulic lines due to their strength and resistance to vibration.

8. Nuclear Power Plants

These pipes are used in nuclear power plants for their ability to withstand high radiation levels and maintain integrity over long periods.

9. Suburban Water Supply Systems

Alloy steel seamless pipes are used in suburban water supply systems for their reliability and resistance to corrosion, ensuring clean water delivery.

10. Industrial Heat Exchangers

In various industries, alloy steel seamless pipes are used in heat exchangers for their ability to handle high temperatures and pressures without failure.

Conclusion

Alloy seamless pipes are an excellent choice for projects that require high strength, durability, and resistance to corrosion. Their seamless construction ensures a uniform and reliable product that can withstand the rigors of demanding applications. As the demand for high-performance piping solutions grows, alloy seamless pipes will continue to be a preferred option in various industries. Investing in alloy seamless pipes for your project can lead to long-term cost savings, increased efficiency, and improved safety.

FAQ

What are alloy seamless pipes?

Alloy steel seamless pipes are tubular products made from alloy steel, manufactured without any weld seam, providing a smooth inner surface and superior resistance to pressure and corrosion.

What are the key features of alloy steel seamless pipes?

Key features include high strength, corrosion resistance, temperature tolerance, dimensional accuracy, and a long service life.

What are the main applications of alloy steel seamless pipes?

Main applications include industrial and process piping, the oil and gas industry, power generation, chemical processing, and construction and infrastructure.

What are the main specifications to consider when selecting alloy steel seamless pipes?

Main specifications include material, seamless construction, wall thickness, outer diameter, temperature resistance, and pressure rating.

How do alloy steel seamless pipes compare to other types of pipes?

Alloy steel seamless pipes offer superior strength and corrosion resistance compared to carbon steel pipes, making them suitable for more demanding applications. Their seamless construction also provides better pressure resistance and a smoother inner surface compared to welded pipes.