Introduction

In recent years, corrugated metal sheeting has become a popular choice in the construction industry due to its durability, aesthetic appeal, and versatility. This material can be utilized in various applications, from roofing and siding to fencing and decorative elements. As construction trends evolve, the demand for sustainable and cost-effective building materials increases, making corrugated metal sheeting a top contender. This blog explores the versatility of corrugated metal sheeting in construction, highlighting its benefits, applications, and installation methods.

What is Corrugated Metal Sheeting?

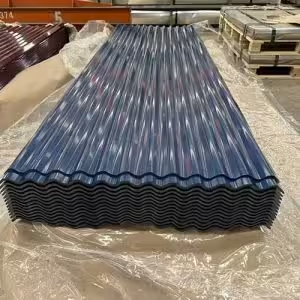

Understanding Corrugated Metal Sheeting

Corrugated metal sheeting is a type of material characterized by its wavy or ridged pattern. This design provides structural strength while minimizing weight, making it an ideal choice for numerous construction applications. Typically made from steel, aluminum, or galvanized metal, corrugated sheets are treated to withstand various environmental factors, including rust, corrosion, and extreme weather conditions.

Key Features of Corrugated Metal Sheeting

- Lightweight: Easy to transport and handle, reducing labor costs.

- Durable: Resistant to harsh weather, pests, and fire, ensuring longevity.

- Low Maintenance: Requires minimal upkeep compared to traditional materials.

- Versatile Design: Available in various colors and finishes to suit aesthetic preferences.

Benefits of Using Corrugated Metal Sheeting in Construction

1. Cost-Effectiveness

One of the primary advantages of using corrugated metal sheeting is its cost-effectiveness. This material is generally more affordable than traditional building materials like wood or concrete. The lightweight nature of corrugated sheets also reduces transportation and installation costs, allowing construction projects to stay within budget.

2. Speed of Installation

Corrugated metal sheeting is designed for easy installation, often featuring interlocking edges or fasteners that simplify the process. This speed of installation can significantly reduce labor costs and project timelines, making it an ideal choice for contractors looking to complete projects quickly.

3. Environmental Sustainability

With growing concerns about environmental sustainability, many construction projects seek eco-friendly materials. Corrugated metal sheeting is often made from recycled materials and can be fully recycled at the end of its life cycle. Its energy-efficient production process and reflective properties also contribute to energy savings in buildings.

4. Aesthetic Flexibility

Available in a variety of colors and finishes, corrugated metal sheeting can enhance the visual appeal of a building. Whether used as roofing, siding, or decorative accents, it can complement various architectural styles, from modern to rustic.

5. Exceptional Weather Resistance

Corrugated metal sheeting is designed to withstand the elements, including heavy rain, snow, wind, and UV exposure. Its resistance to rust and corrosion, especially when galvanized, makes it suitable for diverse climates, ensuring that buildings remain protected over time.

Applications of Corrugated Metal Sheeting in Construction

1. Roofing Solutions

Corrugated metal sheeting is widely used in roofing applications due to its lightweight and durable nature. It can be installed over existing roofs, reducing waste and the need for extensive renovations. Additionally, its reflective properties help reduce heat absorption, contributing to energy efficiency.

2. Siding and Wall Cladding

Using corrugated metal sheeting as siding provides a modern and industrial look to buildings. Its durability and low maintenance requirements make it an attractive option for commercial and residential properties. Available in various colors, it allows homeowners to express their style while ensuring protection against the elements.

3. Fencing and Privacy Screens

Corrugated metal sheeting is increasingly being used for fencing and privacy screens. Its robust nature offers excellent security while creating a stylish barrier. The design can be customized to fit specific heights and configurations, making it a versatile choice for property owners.

4. Agricultural Uses

In agricultural settings, corrugated metal sheeting is often used for barn roofs, storage facilities, and livestock shelters. Its weather resistance ensures that animals and equipment are protected from harsh environmental conditions.

5. Decorative Elements

Beyond functional applications, corrugated metal sheeting can also be used for decorative purposes. Interior designers are incorporating it into walls, ceilings, and accents, adding an industrial touch to residential and commercial spaces.

Comparison of Corrugated Metal Sheeting Types

To help you choose the right corrugated metal sheeting for your project, here’s a comparison of common types:

| Type | Material | Thickness | Common Applications |

|---|---|---|---|

| Steel Corrugated | Steel | 26-20 gauge | Roofing, Siding |

| Aluminum Corrugated | Aluminum | 24-18 gauge | Roofing, Fencing, Decorative Elements |

| Galvanized Steel | Galvanized Steel | 26-20 gauge | Roofing, Siding, Agricultural Structures |

| Zinc Coated | Steel | 26-20 gauge | Roofing, Siding |

From the table, it’s clear that different types of corrugated metal sheeting have varying costs and applications, allowing for flexibility based on project needs.

Installation Tips for Corrugated Metal Sheeting

1. Preparing the Surface

Before installing corrugated metal sheeting, ensure that the underlying surface is clean and dry. If applying over existing materials, check for any loose or damaged areas that may need repair.

2. Measuring and Cutting

Accurate measurements are crucial for a successful installation. Use proper cutting tools designed for metal to avoid jagged edges. Mark your measurements clearly before cutting to ensure a clean finish.

3. Securing the Sheets

When securing the sheets, use appropriate fasteners designed for corrugated metal sheeting. These fasteners should be spaced adequately to ensure stability while allowing for thermal expansion and contraction.

4. Overlapping Sheets

To ensure water runoff, overlap the sheets as recommended, typically by one to two corrugations. This helps prevent leaks and enhances the waterproofing capabilities of the installation.

5. Regular Maintenance

Once installed, conduct regular inspections to identify any signs of damage or wear. Cleaning the sheets periodically will help maintain their appearance and functionality.

Conclusion

The versatility of corrugated metal sheeting in construction is undeniable. With its cost-effectiveness, rapid installation, aesthetic appeal, and resistance to harsh weather conditions, it has become a preferred choice for various applications. Whether you are a contractor, architect, or homeowner, considering corrugated metal sheeting can enhance your project’s durability and visual appeal. As construction continues to evolve, embracing innovative materials like corrugated metal sheeting will lead to more sustainable and efficient building practices.

FAQ

What is corrugated metal sheeting?

Corrugated metal sheeting is a lightweight material characterized by its wavy or ridged pattern, offering strength and durability. It is commonly used for roofing, siding, fencing, and decorative elements.

What are the benefits of using corrugated metal sheeting?

The benefits include cost-effectiveness, speed of installation, environmental sustainability, aesthetic flexibility, and exceptional weather resistance.

How long does corrugated metal sheeting last?

With proper installation and maintenance, corrugated metal sheeting can last 30 years or more, depending on the material and environmental conditions.

Can corrugated metal sheeting be recycled?

Yes, corrugated metal sheeting is recyclable, making it an eco-friendly option in construction.