Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

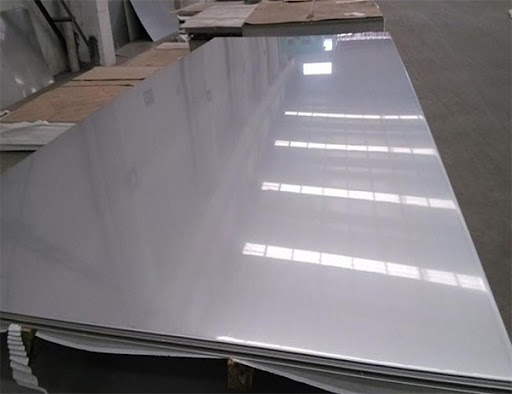

Steel metal plates are flat, rigid sheets made from steel that come in various thicknesses and dimensions. They are commonly used for structural and industrial purposes due to their exceptional strength, flexibility, and resistance to corrosion. Steel plates can be cut, welded, or formed into various shapes, making them a versatile material for many types of manufacturing and construction projects.

These plates are available in different grades and types, each offering specific properties tailored to meet the needs of particular industries. Whether you’re building a bridge, manufacturing a piece of heavy machinery, or constructing a commercial building, steel plates are likely to be part of the materials used.

The Importance of Choosing the Right Steel Plate

Selecting the appropriate type of steel plate is crucial because it can affect the overall strength, durability, and cost-effectiveness of a project. Different grades and types of steel offer varying levels of strength, resistance to wear, and suitability for specific environments. For instance, stainless steel plates offer superior corrosion resistance, while carbon steel plates are known for their high strength-to-weight ratio and affordability.

In this post, we will examine several common types of steel plates and their key features to help you make an informed decision for your next project.

Types of Steel Metal Plates

Carbon Steel Plates

Carbon steel is one of the most widely used types of steel metal plates, known for its strength, versatility, and cost-effectiveness. These plates are made by combining iron and carbon, and the percentage of carbon in the steel can influence its strength, hardness, and ductility.

- Low-Carbon Steel Plates: These plates have a carbon content of around 0.05% to 0.25%, making them relatively soft and easy to shape. They are commonly used in the construction and manufacturing of automotive components, structural frames, and general-purpose applications.

- Medium-Carbon Steel Plates: With a carbon content of 0.30% to 0.60%, medium-carbon steel plates offer a balance between strength and ductility. They are ideal for applications that require moderate strength, such as manufacturing tools and machine components.

- High-Carbon Steel Plates: These plates contain more than 0.60% carbon and are known for their hardness and strength. They are typically used in applications requiring high wear resistance, such as in the production of cutting tools and industrial equipment.

Stainless Steel Plates

Stainless steel is known for its excellent resistance to corrosion, making it a popular choice for industries where exposure to moisture, chemicals, and extreme temperatures is common. Stainless steel plates are made by alloying steel with chromium, which gives them their corrosion-resistant properties.

- Austenitic Stainless Steel Plates: These plates are made with high amounts of chromium and nickel, making them non-magnetic and highly resistant to corrosion. They are often used in food processing, medical equipment, and chemical industries.

- Ferritic Stainless Steel Plates: These plates are magnetic and have a lower chromium content than austenitic stainless steel. They are typically used in automotive and construction applications where high corrosion resistance is needed but at a lower cost.

- Martensitic Stainless Steel Plates: These plates have high carbon content, which provides increased hardness and strength. They are commonly used in applications such as turbines, pumps, and knives, where both strength and resistance to wear are required.

Alloy Steel Plates

Alloy steel plates are made by adding other elements, such as manganese, nickel, or molybdenum, to the steel to enhance specific properties. These plates are designed for applications requiring superior strength, toughness, and resistance to wear and fatigue.

- Low-Alloy Steel Plates: These plates contain a small percentage of alloying elements (less than 5%) and are used in a variety of industrial applications, including the manufacturing of pipelines, pressure vessels, and heavy machinery.

- High-Alloy Steel Plates: With higher percentages of alloying elements, high-alloy steel plates offer enhanced properties such as increased hardness, wear resistance, and resistance to heat. These plates are commonly used in extreme environments, such as in aerospace and power generation industries.

Mild Steel Plates

Mild steel, also known as low-carbon steel, is one of the most common types of steel used in manufacturing and construction. It has a low carbon content, making it easy to weld, cut, and shape. Mild steel plates are relatively inexpensive compared to other types of steel plates, making them an attractive option for projects with budget constraints.

These plates are used in a wide variety of applications, including construction, automotive manufacturing, and general engineering projects. Mild steel plates offer good strength and flexibility, though they are more susceptible to corrosion than stainless steel or alloy steel plates.

Structural Steel Plates

Structural steel plates are used in the construction of large, load-bearing structures such as bridges, buildings, and ships. These plates are designed to provide exceptional strength and support to structures that experience high levels of stress and strain.

Weather-Resistant Steel Plates: Some structural steel plates are designed to resist the effects of weathering and corrosion, making them ideal for outdoor or maritime applications. They are commonly used in the construction of ships, offshore platforms, and bridges in harsh environments.

High-Strength Structural Steel Plates: These plates are designed to withstand significant loads and are often used in applications such as skyscraper construction, bridges, and heavy machinery.

Steel Metal Plates Comparison Table

The following table provides a comparison of different types of steel plates based on their properties and typical applications:

| Steel Plate Type | Strength | Corrosion Resistance | Weldability | Common Applications |

|---|---|---|---|---|

| Carbon Steel Plates | High | Moderate | Excellent | Construction, automotive, general fabrication |

| Stainless Steel Plates | Moderate to High | Excellent | Good | Food processing, medical equipment, chemical industries |

| Alloy Steel Plates | Very High | High (depending on alloy) | Moderate to Good | Heavy machinery, pressure vessels, aerospace |

| Mild Steel Plates | Moderate | Low to Moderate | Excellent | Construction, automotive, general engineering |

| Structural Steel Plates | Very High | Moderate | Good | Bridges, skyscrapers, shipbuilding |

As shown in the table, each type of steel plate has distinct properties that make it suitable for different applications. The choice of steel plate depends on the specific requirements of your project, including strength, corrosion resistance, and cost.

Conclusion

Steel metal plates are a crucial component in numerous industries due to their strength, versatility, and availability. Understanding the differences between the various types of steel plates can help you select the right material for your project, whether you’re building a structure, manufacturing machinery, or creating custom components.

When choosing a steel plate, it’s important to consider factors such as strength, corrosion resistance, weldability, and cost. By evaluating these properties and matching them to the needs of your project, you can ensure that you select the optimal steel plate for the job.

FAQ

What is the most common type of steel plate?

The most common type of steel plate is carbon steel, which is used in a wide range of applications due to its balance of strength, affordability, and ease of use.

What are the main industries that use steel metal plates?

Steel metal plates are widely used in industries such as construction, automotive, shipbuilding, aerospace, and manufacturing. They are essential for creating structural frameworks, machinery components, and specialized equipment.

How are steel metal plates manufactured?

Steel metal plates are produced through processes like hot rolling or cold rolling. Hot rolling is used for thicker plates, while cold rolling is typically reserved for thinner, more precise applications.

What are the advantages of using steel metal plates in construction?

Steel metal plates offer exceptional strength, durability, and versatility, making them ideal for construction projects. They can withstand heavy loads, resist wear, and be customized to fit specific architectural or structural requirements.

How do I maintain steel metal plates to prevent corrosion?

To maintain steel metal plates and prevent corrosion, you can use protective coatings such as paint, galvanization, or powder coating. Regular cleaning and inspections are also important to ensure longevity.

Are steel metal plates environmentally sustainable?

Yes, steel metal plates are highly recyclable, making them an environmentally sustainable option. Steel can be melted down and reused without losing its properties, which reduces waste and energy consumption in production.