Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

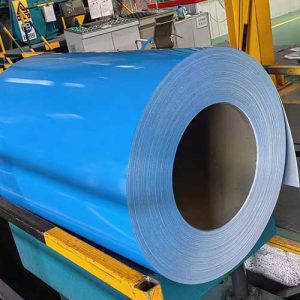

Galvanized steel coil is a versatile and essential material in the construction industry, renowned for its corrosion resistance and durability. The process of galvanizing involves coating steel with a layer of zinc, which provides a protective barrier against environmental elements that can cause rust and degradation. This comprehensive guide will explore the advantages of using galvanized steel coil in construction, its properties, applications, and how it can enhance the longevity and sustainability of building projects.

Benefits of Galvanized Steel Coil in Construction

Enhanced Corrosion Resistance

One of the primary benefits of galvanized steel coil is its exceptional corrosion resistance. The zinc coating acts as a sacrificial anode, corroding preferentially to the steel and thereby protecting it from rust and corrosion. This is particularly important in construction, where materials are often exposed to harsh weather conditions and other environmental stresses .

Versatility in Applications

Galvanized steel coil can be used in a wide range of construction applications, including roofing, wall cladding, structural components, and framing. Its versatility makes it suitable for both interior and exterior use, as well as for a variety of architectural styles and designs .

Improved Structural Integrity

The zinc coating on galvanized steel coil not only protects against corrosion but also enhances the material’s structural integrity. The coating provides additional strength and rigidity, making it an ideal choice for load-bearing applications such as beams and columns .

Cost-Effectiveness

Galvanized steel coil offers a cost-effective solution for construction projects. The initial investment may be higher than for some alternative materials, but the long-term benefits of reduced maintenance and extended lifespan make it an economical choice. The protective coating means that galvanized steel requires less frequent painting and repair, saving on ongoing maintenance costs .

Sustainability and Recyclability

Galvanized steel coil is a sustainable construction material. The zinc coating extends the life of the steel, reducing the need for replacement and the associated environmental impact of material production. Additionally, galvanized steel is 100% recyclable, contributing to the circular economy and minimizing waste .

Applications of Galvanized Steel Coil in Construction

Roofing and Cladding

Galvanized steel coil is extensively used in roofing and wall cladding due to its resistance to weathering and its ability to maintain its appearance over time. The protective zinc coating stands up to UV radiation, rain, snow, and temperature fluctuations, ensuring long-lasting performance .

Structural Components

In structural applications, galvanized steel coil provides the necessary strength and durability required for supports and frameworks. Its high strength-to-weight ratio and load-bearing capabilities make it ideal for constructing bridges, warehouses, and other structures that demand robust support systems .

Agricultural and Industrial Buildings

Galvanized steel coil is also used in the construction of agricultural and industrial buildings, where it is exposed to harsh conditions and potential corrosive substances. The protective zinc coating ensures that these structures remain operational and maintain their integrity over time .

Best Practices for Using Galvanized Steel Coil

Selection of Appropriate Grade

When selecting galvanized steel coil for a construction project, it is important to choose the appropriate grade and thickness based on the specific requirements of the application. Different grades offer varying levels of strength and corrosion resistance, and the thickness of the zinc coating can also impact performance .

Adherence to Standards

Galvanized steel coil should meet recognized industry standards, such as ASTM A653 or EN 10346, which specify the minimum zinc coating weights and other quality requirements. These standards ensure that the material will perform as expected and provide the necessary corrosion protection .

Proper Installation and Handling

To maintain the integrity of the zinc coating and the underlying steel, galvanized steel coil should be handled and installed with care. This includes using appropriate lifting equipment, avoiding contact with sharp or abrasive materials, and ensuring that the coil is properly supported during transportation and installation .

Regular Inspection and Maintenance

While galvanized steel coil is highly resistant to corrosion, regular inspections and maintenance are still important to ensure the long-term performance of the material. This includes checking for signs of damage or corrosion and addressing any issues promptly to prevent further deterioration .

Comparative Analysis of Galvanized Steel Coil with Other Materials

| Property | Galvanized Steel Coil | Other Materials |

|---|---|---|

| Corrosion Resistance | High | Varies |

| Strength | High | Varies |

| Durability | Long-lasting | Varies |

| Cost-Effectiveness | Costly initially, cost-effective long-term | Depends on material |

| Recyclability | 100% recyclable | Varies |

Conclusion

Galvanized steel coil is an invaluable material in the construction industry, offering a range of benefits that enhance the longevity, durability, and sustainability of building projects. Its exceptional corrosion resistance, versatility, and strength make it an ideal choice for a variety of applications, from residential to commercial and industrial construction. By selecting the appropriate grade and adhering to best practices for installation and maintenance, galvanized steel coil can provide a long-lasting and cost-effective solution for construction projects.

FAQ

What are the different types of galvanization processes?

There are two main types of galvanization processes: hot-dip galvanization and electro-galvanization. Hot-dip galvanization involves immersing the steel in molten zinc, resulting in a thick and durable coating. Electro-galvanization uses an electric current to apply a thinner layer of zinc to the steel surface .

How does galvanized steel coil compare to other materials in terms of sustainability?

Galvanized coil is more sustainable than many other materials due to its long lifespan, which reduces the need for frequent replacement. Additionally, it is 100% recyclable, contributing to the circular economy and minimizing waste .

Are there any limitations to using galvanized coil in construction?

While galvanized coil offers many advantages, it may not be suitable for all applications. For example, it may not be the best choice for environments with extremely high temperatures, as the zinc coating can degrade over time .