Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

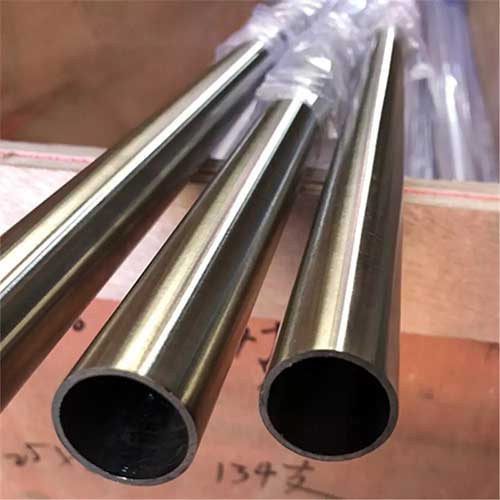

Stainless steel seamless pipes are one of the most essential components used across various industries, thanks to their unique properties of strength, durability, and resistance to corrosion. Unlike welded pipes, seamless pipes are made from a single piece of stainless steel, which makes them more robust and capable of handling higher pressures and temperatures. These pipes are widely used in applications ranging from oil and gas pipelines to food processing equipment and chemical industries.

In this article, we will explore the advantages of stainless steel seamless pipes, their common applications, and key considerations when choosing the right stainless steel seamless pipe for your project. Whether you are working in construction, manufacturing, or any other sector that requires durable piping, understanding the full potential of stainless steel seamless pipes is crucial for optimizing performance and cost.

What Are Stainless Steel Seamless Pipes?

The Manufacturing Process of Stainless Steel Seamless Pipes

A stainless steel seamless pipe is made from a solid billet of stainless steel that is heated and pierced to create a hollow tube. The process does not involve welding, which is why these pipes are referred to as “seamless.” The process involves several steps:

- Heating the Billet: The stainless steel is heated in a furnace until it becomes malleable.

- Piercing: The heated billet is pierced to create a hollow core.

- Extrusion and Stretching: The billet is stretched and elongated to form the pipe’s desired dimensions.

- Sizing: The pipe is passed through a series of rollers to achieve its final diameter and thickness.

- Cooling and Finishing: Finally, the pipe is cooled, straightened, and cut into desired lengths.

This method ensures that stainless steel seamless pipes have a smooth, uniform surface and consistent strength throughout the length of the pipe, making them ideal for high-pressure and high-temperature applications.

Key Features of Stainless Steel Seamless Pipes

Stainless steel seamless pipes offer several distinct features that set them apart from welded pipes:

- Strength and Durability: The seamless construction means that there are no welded seams, which makes the pipe stronger and less prone to failure under stress.

- Corrosion Resistance: Stainless steel’s inherent resistance to corrosion makes seamless pipes suitable for harsh environments, including exposure to chemicals, moisture, and extreme temperatures.

- High Pressure and Temperature Tolerance: Due to the absence of seams, stainless steel seamless pipes are ideal for handling high-pressure and high-temperature fluids and gases.

- Smooth Surface: The absence of seams leads to a smoother inner surface, reducing friction and enhancing the flow of liquids or gases.

Advantages of Stainless Steel Seamless Pipes

1. Improved Strength and Performance

The primary advantage of stainless steel seamless pipes is their superior strength. Unlike welded pipes, which may develop weak spots at the weld seam, seamless pipes maintain uniform strength throughout their length. This makes them ideal for applications requiring high strength and pressure, such as in the oil and gas industry, chemical processing, and power generation.

2. Resistance to Corrosion and Chemical Damage

Stainless steel is highly resistant to corrosion, making stainless steel seamless pipes suitable for use in harsh environments. They can withstand exposure to a variety of corrosive materials, including acids, salts, and alkalis. This resistance makes them ideal for industries such as chemical manufacturing, water treatment, and food processing.

3. Better Flow Characteristics

The seamless construction of these pipes ensures a smoother inner surface, which minimizes resistance to the flow of liquids and gases. This leads to increased efficiency in applications such as fluid transport systems, where maintaining flow rate and reducing friction losses are critical.

4. Higher Pressure Tolerance

Stainless steel seamless pipes are known for their ability to withstand high pressures. Because there are no welds to weaken the structure, these pipes are often used in high-pressure applications, such as in oil and gas pipelines, pressure vessels, and steam boilers.

5. Versatility in Applications

Due to their strength, corrosion resistance, and high-pressure tolerance, stainless steel seamless pipes are used in a wide range of applications across various industries, including:

- Oil and Gas: Transporting crude oil, natural gas, and refined products.

- Chemical Processing: Used in reactors, distillation columns, and other equipment that handle corrosive chemicals.

- Food and Beverage: For applications such as dairy piping and brewing systems, where sanitation and corrosion resistance are critical.

- Aerospace: In high-performance applications like fuel lines and hydraulic systems.

Common Applications of Stainless Steel Seamless Pipes

1. Oil and Gas Industry

Stainless steel seamless pipes are widely used in the oil and gas industry to transport both refined products and raw materials. Their resistance to high pressures, corrosion, and high temperatures makes them ideal for offshore pipelines, drilling operations, and gas transport systems. These pipes are also used for refining equipment, where the pipes must handle both high temperatures and corrosive materials.

2. Chemical and Petrochemical Industries

In the chemical processing and petrochemical industries, stainless steel seamless pipes are often used for their resistance to corrosion and the ability to handle high temperatures and pressures. They are used in reactors, distillation columns, and piping systems that carry corrosive chemicals. The smooth surface also reduces the risk of contamination, which is essential in sensitive processes.

3. Water and Wastewater Treatment

Stainless steel seamless pipes are highly effective in water and wastewater treatment plants due to their resistance to rust and corrosion, especially in environments with highly acidic or alkaline conditions. They are used for conveying treated water, sewage, and chemicals used in treatment processes.

4. Food and Beverage Industry

In the food and beverage industry, hygiene and sanitation are critical, which is why stainless steel seamless pipes are commonly used in food processing systems. These pipes are non-reactive, easy to clean, and resistant to contamination, making them ideal for dairy, brewing, and soft drink production systems.

5. Pharmaceutical Industry

Seamless stainless steel pipes are frequently used in pharmaceutical manufacturing, especially where sanitary standards are important. They are employed in systems that handle fluids, powders, or gases used in the production of medicines. Their corrosion resistance and smooth surface prevent contamination and ensure the safety and quality of the final products.

Stainless Steel Seamless Pipe Grades and Specifications

Stainless steel seamless pipes come in different grades and specifications, depending on their intended application. Some of the most commonly used grades include:

| Grade | Composition | Applications |

|---|---|---|

| 304 | 18% Chromium, 8% Nickel, Balance Iron | General purpose, food, beverage, and pharmaceutical industries |

| 316 | 16% Chromium, 10% Nickel, 2% Molybdenum, Balance Iron | Chemical and marine environments, saltwater applications |

| 321 | 17% Chromium, 9% Nickel, Titanium addition | High temperature applications, such as in aerospace |

| 410 | 11.5% Chromium, Balance Iron | High strength, used in applications with moderate corrosion |

Choosing the Right Stainless Steel Seamless Pipe

When selecting a stainless steel seamless pipe for a specific application, it’s important to consider factors such as corrosion resistance, strength, temperature tolerance, and pressure requirements. Each application may require a specific grade of stainless steel to meet the desired performance standards.

Conclusion

Stainless steel seamless pipes offer exceptional performance in a wide range of industries due to their strength, resistance to corrosion, and ability to handle high pressure and temperature conditions. Whether you are working in the oil and gas sector, chemical manufacturing, or food processing, understanding the advantages and applications of stainless steel seamless pipes is essential for selecting the right material for your needs. Their superior quality, combined with the diverse range of grades available, makes them a reliable choice for various demanding applications.

FAQ

What is the difference between welded and seamless stainless steel pipes?

Welded pipes have a seam where two pieces of metal are joined, while seamless pipes are made from a single piece of stainless steel. Seamless pipes tend to be stronger and more resistant to pressure and corrosion because they lack a welded seam.

What are the most common grades of stainless steel used in seamless pipes?

The most common grades are 304, 316, 321, and 410. Each grade offers unique characteristics for different applications, such as resistance to corrosion or high-temperature tolerance.

Why are seamless stainless steel pipes more expensive than welded pipes?

Seamless pipes require more advanced manufacturing techniques and equipment. The process of forming seamless pipes is more complex, which makes the production cost higher.

Can stainless steel seamless pipes be used for high-temperature applications?

Yes, stainless steel seamless pipes are well-suited for high-temperature applications, especially grades like 316 and 321, which are designed to withstand extreme temperatures.

What industries use stainless steel seamless pipes?

Industries like oil and gas, chemical processing, food and beverage, pharmaceuticals, aerospace, and water treatment commonly use stainless steel seamless pipes due to their durability, resistance to corrosion, and high strength.