Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

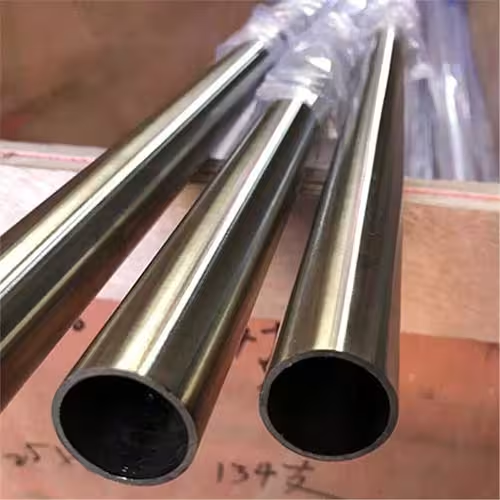

Stainless steel pipes are essential components in a wide variety of industries, from construction and plumbing to aerospace and pharmaceuticals. Due to their resistance to corrosion, high strength, and durability, stainless steel pipes are the material of choice for projects that require reliability and longevity. However, with the wide variety of stainless steel pipe sizes available, choosing the right size for your application can be a daunting task.

In this comprehensive guide, we’ll explore the different stainless steel pipe sizes, their applications, and how to select the right size for your project. Whether you’re working on plumbing, structural, or industrial applications, understanding stainless steel pipe sizes is crucial for ensuring that your system functions efficiently and reliably.

Understanding Stainless Steel Pipe Sizes

Stainless steel pipe sizes are typically described by two measurements: nominal pipe size (NPS) and schedule (SCH). These two factors determine the diameter and wall thickness of a pipe, respectively. Both of these measurements are essential for ensuring the pipe fits properly and performs as expected in its intended application.

Nominal Pipe Size (NPS)

The nominal pipe size (NPS) is a standard used to identify the pipe’s diameter. The term “nominal” means that the measurement is approximate and not exact. NPS is commonly used in both U.S. and international pipe systems, and it correlates to the inner diameter (ID) of the pipe.

- Common Sizes: Stainless steel pipes come in a range of NPS sizes, from small sizes like NPS 1/8 inch to larger sizes such as NPS 24 inches and beyond.

- Measurement: The NPS number corresponds to a pipe’s nominal size, but the actual outside diameter (OD) of the pipe is usually larger than the NPS. For example, a pipe with an NPS of 2 inches typically has an OD of 2.375 inches.

Pipe Schedule (SCH)

The schedule (SCH) indicates the wall thickness of the pipe, which is crucial for determining the strength and pressure rating of the pipe. The schedule number (e.g., SCH 40, SCH 80, SCH 160) defines the wall thickness, with higher numbers indicating thicker walls.

- Common Schedules: SCH 40, SCH 80, SCH 160 are the most commonly used schedules for stainless steel pipes.

- Application: The schedule is critical for determining how much pressure the pipe can withstand. Thicker-walled pipes are necessary for high-pressure applications.

Stainless Steel Pipe Diameter

The diameter of the pipe is critical for flow rate calculations. The pipe’s diameter is typically classified as either outside diameter (OD) or inside diameter (ID), depending on the application.

- OD: The outside diameter is used when measuring pipe size externally.

- ID: The inside diameter is critical when the flow of the material through the pipe is the focus.

Types of Stainless Steel Pipes and Their Sizes

Stainless steel pipes are classified into various types depending on their shape, material, and application. Below are some of the most common types:

Welded Stainless Steel Pipes

Welded stainless steel pipes are produced by welding a flat piece of stainless steel into a cylindrical shape. These pipes are typically used in construction and other non-critical applications.

- Available Sizes: NPS 1/8 inch to NPS 24 inches

- Applications: Plumbing, HVAC systems, water pipelines

Seamless Stainless Steel Pipes

Seamless pipes are made without a seam or weld and are generally stronger and more resistant to pressure than welded pipes. These pipes are often used in high-pressure and critical applications.

- Available Sizes: NPS 1/8 inch to NPS 24 inches

- Applications: Oil and gas, chemical processing, pharmaceutical industries

Schedule 40 Stainless Steel Pipes

Schedule 40 pipes are commonly used in water distribution systems, and they are suitable for low- to medium-pressure applications.

- Available Sizes: NPS 1/8 inch to NPS 24 inches

- Applications: Plumbing, irrigation systems, drainage

Schedule 80 Stainless Steel Pipes

Schedule 80 pipes have thicker walls than Schedule 40 pipes, allowing them to withstand higher pressures. These pipes are commonly used in chemical and industrial applications.

- Available Sizes: NPS 1/8 inch to NPS 24 inches

- Applications: Chemical processing, high-pressure systems, steam lines

Schedule 160 Stainless Steel Pipes

Schedule 160 pipes have the thickest walls and are used in the most demanding applications where high pressure and durability are critical.

- Available Sizes: NPS 1/8 inch to NPS 12 inches

- Applications: High-pressure gas and fluid lines, industrial and military applications

Stainless Steel Pipe Size Chart

Below is a chart showing the typical dimensions of stainless steel pipes based on different NPS sizes and schedules.

| NPS Size | Schedule 40 Pipe (OD x Wall Thickness) | Schedule 80 Pipe (OD x Wall Thickness) | Schedule 160 Pipe (OD x Wall Thickness) |

|---|---|---|---|

| 1/8″ | 0.405″ x 0.049″ | 0.405″ x 0.065″ | 0.405″ x 0.083″ |

| 1/4″ | 0.540″ x 0.065″ | 0.540″ x 0.080″ | 0.540″ x 0.104″ |

| 1/2″ | 0.840″ x 0.109″ | 0.840″ x 0.140″ | 0.840″ x 0.179″ |

| 1″ | 1.315″ x 0.140″ | 1.315″ x 0.179″ | 1.315″ x 0.226″ |

| 2″ | 2.375″ x 0.154″ | 2.375″ x 0.218″ | 2.375″ x 0.276″ |

| 4″ | 4.500″ x 0.237″ | 4.500″ x 0.337″ | 4.500″ x 0.443″ |

| 6″ | 6.625″ x 0.280″ | 6.625″ x 0.432″ | 6.625″ x 0.552″ |

How to Choose the Right Stainless Steel Pipe Size

Identify the Application and Pressure Requirements

The first step in selecting the right stainless steel pipe size is understanding the application’s pressure requirements. For low-pressure systems, Schedule 40 pipes are often sufficient. However, for high-pressure applications, Schedule 80 or Schedule 160 pipes should be used.

Consider the Material Type

Certain types of stainless steel, such as 304 and 316 stainless steel, offer different levels of corrosion resistance. Choose a material that suits your environmental and chemical exposure conditions.

Evaluate the Flow Rate

When selecting a stainless steel pipe size, consider the pipe’s flow rate and the space in which it will be installed. Larger pipes may be needed for systems with high flow rates.

Check for Compatibility

Ensure that the pipe size you choose is compatible with other components in your system, such as valves, fittings, and flanges.

Conclusion

Stainless steel pipes are essential components in various industries, and selecting the right size is critical to the performance, durability, and efficiency of your system. By understanding the different stainless steel pipe sizes, schedules, and material types, you can ensure that you choose the appropriate pipe for your specific needs.

Whether you are working in construction, plumbing, or chemical processing, choosing the right stainless steel pipe size is key to ensuring optimal system performance.

FAQ

What is the difference between Schedule 40 and Schedule 80 stainless steel pipes?

Schedule 80 pipes have thicker walls than Schedule 40 pipes, which makes them suitable for higher pressure applications.

How do I determine the correct pipe size for my project?

Consider the pressure requirements, flow rate, material type, and compatibility with other system components when choosing the right pipe size.

Can stainless steel pipes be used for high-temperature applications?

Yes, stainless steel pipes can be used in high-temperature environments, especially those made from alloys like 316 stainless steel.

What is the most commonly used stainless steel pipe size?

NPS 2-inch pipes are commonly used in various applications, such as plumbing and industrial systems.

Are there other materials for piping systems?

Yes, other materials such as carbon steel, PVC, and copper are also used for piping, depending on the application’s requirements.