Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

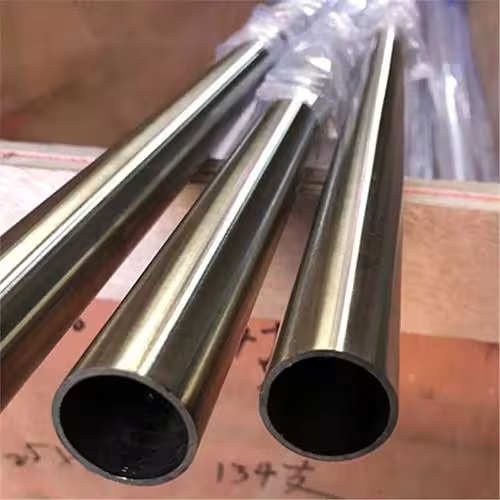

Stainless steel pipes are widely used across various industries, including construction, manufacturing, food processing, and oil and gas. Understanding stainless steel pipe dimensions is essential for selecting the right pipe for specific applications. Pipe dimensions impact flow capacity, pressure ratings, and structural integrity, making them critical for engineering and industrial applications.

This guide provides a comprehensive overview of stainless steel pipe dimensions, covering key measurement parameters, industry standards, applications, and selection criteria. Whether you are an engineer, contractor, or business owner, understanding these dimensions will help you make informed decisions for your piping needs.

Understanding Stainless Steel Pipe Dimensions

Stainless steel pipe dimensions are defined by several factors that determine their fit, performance, and compatibility with other components. The most important parameters include nominal pipe size, outside diameter, wall thickness, and inside diameter.

Nominal Pipe Size (NPS)

Nominal pipe size (NPS) is a standard designation used in North America to identify pipe sizes. It does not always correspond directly to the actual outer diameter. For example, an NPS 2 pipe has an outer diameter of 2.375 inches, rather than exactly 2 inches.

Outside Diameter (OD)

The outside diameter is the external width of the pipe. This measurement is crucial for selecting compatible fittings and connectors. Unlike the nominal pipe size, the outside diameter remains constant regardless of the pipe’s wall thickness.

Wall Thickness (Schedule)

The schedule of a pipe refers to its wall thickness, which determines its pressure-bearing capacity. Common schedules include SCH 5, SCH 10, SCH 40, and SCH 80. Higher schedules indicate thicker walls and increased durability.

Inside Diameter (ID)

The inside diameter is the space available for fluid or gas flow. It is calculated by subtracting twice the wall thickness from the outside diameter. The inside diameter is crucial for determining the flow rate and pressure drop in a piping system.

Pipe Length

Stainless steel pipes are typically available in standard lengths such as 6 meters (20 feet) and 12 meters (40 feet). Custom lengths can be manufactured based on project requirements.

Industry Standards for Stainless Steel Pipe Dimensions

Various industry standards regulate stainless steel pipe dimensions to ensure consistency and compatibility in piping applications. The most commonly used standards include:

- ASTM A312: Covers seamless and welded stainless steel pipes for high-temperature and corrosive service

- ASTM A358: Specifies electric fusion welded (EFW) stainless steel pipes

- ASTM A269: Covers seamless and welded stainless steel tubing for general use

- ANSI B36.19: Defines dimensions for stainless steel pipes

- ISO 1127: International standard for stainless steel tube dimensions and tolerances

These standards specify pipe dimensions, material composition, testing methods, and mechanical properties, ensuring compliance with industry regulations.

Common Stainless Steel Pipe Sizes and Applications

Different industries require specific pipe sizes depending on factors such as flow rate, pressure rating, and structural support. The table below highlights standard stainless steel pipe dimensions for common sizes and their typical applications.

Standard Stainless Steel Pipe Dimensions

| Nominal Pipe Size (NPS) | Outside Diameter (OD) | Schedule 10 Wall Thickness | Schedule 40 Wall Thickness | Schedule 80 Wall Thickness | Common Applications |

|---|---|---|---|---|---|

| 1/2 inch | 0.840 in (21.3 mm) | 1.65 mm | 2.77 mm | 3.73 mm | Plumbing, HVAC |

| 1 inch | 1.315 in (33.4 mm) | 2.11 mm | 3.38 mm | 4.55 mm | Food processing, automotive |

| 2 inches | 2.375 in (60.3 mm) | 2.77 mm | 3.91 mm | 5.54 mm | Industrial piping, chemical processing |

| 4 inches | 4.500 in (114.3 mm) | 3.05 mm | 6.02 mm | 8.56 mm | Water supply, oil and gas |

| 6 inches | 6.625 in (168.3 mm) | 4.19 mm | 7.11 mm | 10.97 mm | Structural applications, high-pressure systems |

This table illustrates how stainless steel pipe dimensions vary based on pipe size and wall thickness, influencing their use in different industrial settings.

Choosing the Right Stainless Steel Pipe Dimensions

Selecting the right stainless steel pipe dimensions involves considering several key factors to ensure optimal performance.

Pressure and Temperature Requirements

Pipes used in high-pressure and high-temperature environments require thicker walls to withstand internal forces. For example, SCH 80 pipes are often used in steam lines and oil refineries due to their durability.

Flow Rate and Capacity

The inside diameter directly affects the volume of liquid or gas that can pass through the pipe. A larger inside diameter is recommended for applications requiring high flow rates to minimize friction and pressure loss.

Corrosion Resistance

Different stainless steel grades offer varying levels of corrosion resistance. While all stainless steel pipes resist rust, certain grades, such as 316L, are better suited for harsh environments like marine and chemical processing applications.

Installation and Compatibility

It is important to ensure that the selected pipe dimensions match existing fittings, valves, and flanges to avoid installation issues. Standardized dimensions help maintain compatibility across different piping components.

Conclusion

Understanding stainless steel pipe dimensions is crucial for selecting the right pipe for various industrial, commercial, and residential applications. Factors such as nominal pipe size, outside diameter, wall thickness, and compliance with industry standards play a significant role in determining a pipe’s suitability for specific uses.

By considering pressure ratings, flow rates, corrosion resistance, and installation requirements, engineers and contractors can ensure efficiency and durability in stainless steel piping systems. Stainless steel remains a top choice for industries worldwide due to its strength, longevity, and resistance to harsh conditions.

FAQ

What does schedule mean in stainless steel pipe dimensions?

The schedule of a pipe refers to its wall thickness. Higher schedules indicate thicker walls, which can withstand greater pressure compared to lower schedules.

How do I determine the inside diameter of a stainless steel pipe?

The inside diameter is calculated by subtracting twice the wall thickness from the outside diameter. For example, if an NPS 2 pipe has an OD of 2.375 inches and a wall thickness of 0.154 inches, its ID would be approximately 2.067 inches.

What is the most commonly used stainless steel pipe standard?

ASTM A312 is the most widely used standard for stainless steel pipes, particularly in industrial applications such as chemical processing and oil and gas pipelines.

How does pipe schedule affect weight?

Pipes with higher schedules have thicker walls and are therefore heavier. This increased weight can impact installation, support requirements, and transportation costs.

What are the advantages of using stainless steel pipes?

Stainless steel pipes offer excellent corrosion resistance, high strength, and durability. They are widely used in plumbing, food processing, construction, and industrial applications due to their ability to withstand extreme conditions.

Are stainless steel pipe dimensions the same worldwide?

While many dimensions follow international standards such as ASTM, ANSI, and ISO, slight variations may exist depending on regional manufacturing practices. It is essential to verify the specific standards applicable to your project.