Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

Alloy steel seamless pipes are essential components in industries requiring strength, durability, and high performance. These pipes are widely used in sectors such as energy, construction, chemical processing, and automotive manufacturing due to their excellent mechanical properties and resistance to extreme conditions. Selecting the right alloy steel seamless pipes can significantly impact the efficiency and safety of your projects.

In this blog, we will explore the critical factors to consider when choosing high-quality alloy steel seamless pipes. We’ll discuss their composition, applications, and advantages, provide insights into quality assessment, and address common questions. This comprehensive guide aims to help you make informed decisions and ensure the success of your projects.

What Are Alloy Steel Seamless Pipes?

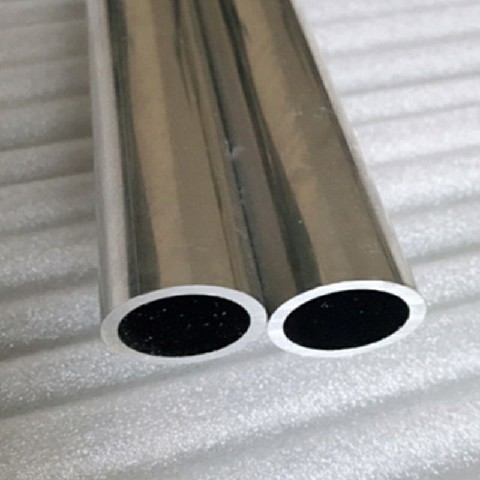

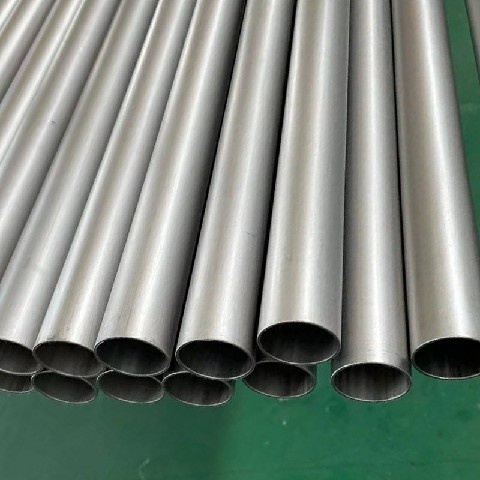

Defining Alloy Steel Seamless Pipes

Alloy steel seamless pipes are made from alloy steel, a material that includes a mix of elements such as manganese, nickel, chromium, molybdenum, and vanadium. Unlike welded pipes, seamless pipes are manufactured without joints or seams, enhancing their strength and reliability.

Types of Alloy Steel Seamless Pipes

- Low-Alloy Steel Pipes: Contain a small percentage of alloying elements for general applications.

- High-Alloy Steel Pipes: Feature higher concentrations of alloying elements, suitable for demanding environments.

- Heat-Resistant Alloy Pipes: Designed to withstand high temperatures in power plants and refineries.

Benefits of Using Alloy Steel Seamless Pipes

Exceptional Strength

Alloy steel seamless pipes are known for their superior tensile and yield strength, making them ideal for high-pressure and high-stress applications.

Corrosion Resistance

The presence of alloying elements such as chromium and molybdenum enhances their resistance to rust, oxidation, and chemical corrosion.

Versatility

These pipes are available in various sizes, grades, and compositions, allowing for customization based on project requirements.

Longevity

Due to their durability, alloy steel seamless pipes require less maintenance and offer a longer service life than other pipe materials.

Heat and Pressure Resistance

Alloy steel seamless pipes can withstand extreme temperatures and pressures, making them suitable for demanding industrial processes.

Key Applications of Alloy Steel Seamless Pipes

Energy Sector

Used in oil and gas pipelines, power plants, and geothermal systems for their heat and pressure tolerance.

Construction

Essential for structural supports, bridges, and infrastructure projects requiring high strength.

Chemical Processing

Resistant to corrosive chemicals, these pipes are used in reactors and storage tanks.

Automotive and Aerospace

Alloy steel seamless pipes are used in engine components and aircraft structures for their lightweight and strength.

Boilers and Heat Exchangers

Perfect for heat-intensive environments in power plants and industrial boilers.

Factors to Consider When Choosing Alloy Steel Seamless Pipes

Material Composition

The alloy composition determines the pipe’s mechanical properties and suitability for specific environments. For example, chromium enhances corrosion resistance, while nickel improves toughness.

Pipe Dimensions

Select the appropriate pipe diameter and thickness to ensure it meets your project’s requirements without compromising safety or performance.

Manufacturing Standards

Ensure the pipes comply with international standards such as ASTM, ASME, or EN to guarantee quality and reliability.

Heat Treatment

Verify whether the pipes have undergone proper heat treatments like annealing or tempering, which improve strength and ductility.

Surface Finish

Inspect the surface for defects such as cracks, uneven finishes, or pitting, which may compromise performance.

Table: Common Grades of Alloy Steel Seamless Pipes and Their Properties

| Grade | Key Alloying Elements | Applications | Features |

|---|---|---|---|

| A335 P11 | Chromium, Molybdenum | Boilers, Power Plants | High heat resistance |

| A335 P22 | Chromium, Molybdenum | Oil and Gas Pipelines | Excellent corrosion resistance |

| A213 T91 | Chromium, Nickel, Molybdenum | Heat Exchangers, Chemical Plants | Superior tensile strength |

| A333 Grade 6 | Carbon, Manganese | Cryogenic Applications | Low-temperature toughness |

| A369 FP91 | Chromium, Molybdenum | High-Pressure Systems | Exceptional creep strength |

This table highlights common grades of alloy steel seamless pipes and their specific uses, helping you match the right material to your project needs.

How to Ensure Quality When Selecting Alloy Steel Seamless Pipes

Inspect Certifications

Always request material test certificates (MTC) to verify the composition and compliance with industry standards.

Perform Ultrasonic Testing

Ultrasonic tests can detect internal flaws or defects in the pipe material.

Evaluate Mechanical Properties

Check for the required tensile strength, yield strength, and elongation properties based on project specifications.

Check Corrosion Resistance

For corrosive environments, ensure the material has adequate resistance through salt spray or immersion tests.

Source from Reputable Suppliers

Choose suppliers with a proven track record in delivering high-quality alloy steel seamless pipes.

Conclusion

Choosing the right alloy steel seamless pipes is a crucial step in ensuring the success and safety of your industrial projects. By understanding the material’s composition, properties, and applications, you can make well-informed decisions. Focus on key factors like material quality, dimensions, and compliance with standards to ensure optimal performance and durability.

Investing in high-quality alloy steel seamless pipes not only enhances efficiency but also minimizes maintenance costs and prolongs the lifespan of your systems. With the knowledge provided in this guide, you’re better equipped to select pipes that meet your specific needs.

FAQ

What are alloy steel seamless pipes?

Alloy steel seamless pipes are pipes made from alloy steel, designed without welded seams for enhanced strength and reliability.

What industries commonly use alloy steel seamless pipes?

These pipes are widely used in industries such as energy, construction, chemical processing, automotive, and aerospace.

How do alloy steel seamless pipes differ from welded pipes?

Seamless pipes are manufactured without joints, providing higher strength and resistance to pressure compared to welded pipes.

What standards should I look for in alloy steel seamless pipes?

Ensure the pipes meet standards such as ASTM A335, A213, or ASME specifications for quality assurance.

How can I test the quality of alloy steel seamless pipes?

Quality can be tested through ultrasonic testing, material certifications, and surface inspections.

What is the benefit of heat-treated alloy steel seamless pipes?

Heat treatment enhances the mechanical properties, such as strength, toughness, and ductility, making the pipes more suitable for demanding applications.

Are alloy steel seamless pipes resistant to corrosion?

Yes, many alloy steel seamless pipes include elements like chromium and molybdenum, which enhance corrosion resistance.

Can alloy steel seamless pipes be used at high temperatures?

Yes, certain grades of alloy steel seamless pipes are specifically designed for high-temperature applications.

What sizes are available for alloy steel seamless pipes?

These pipes come in a range of diameters and thicknesses to meet diverse industrial requirements.

Why is sourcing from a reputable supplier important?

A trusted supplier ensures compliance with standards, quality control, and reliable delivery timelines, reducing project risks.