Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

When it comes to choosing materials for construction, manufacturing, or other industrial applications, two commonly considered options are galvanized sheet metal and stainless steel. Both of these materials have specific advantages depending on the application, and understanding the differences between galvanized sheet metal and stainless steel can help you make the right choice for your project.

This blog will explore the characteristics, benefits, and drawbacks of both galvanized sheet metal and stainless steel, helping you understand which material is best suited for your needs. By comparing factors such as corrosion resistance, cost, strength, and appearance, this article will provide a comprehensive guide to choosing between these two materials.

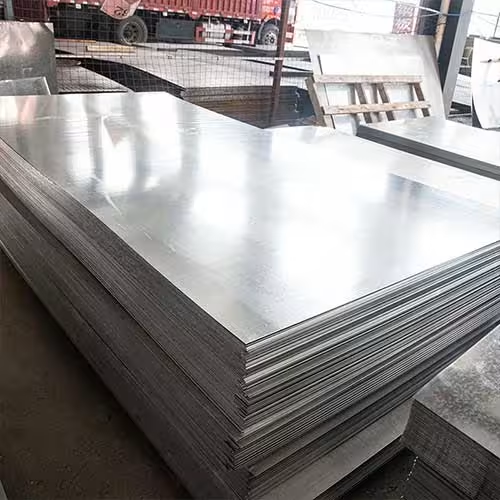

What is Galvanized Sheet Metal?

Galvanized sheet metal is steel that has been coated with a layer of zinc to prevent rust and corrosion. The process, known as galvanization, involves dipping the metal into a bath of molten zinc or applying zinc through electroplating. This creates a durable, rust-resistant surface that protects the underlying steel from harsh environmental conditions.

Key Features of Galvanized Sheet Metal:

- Corrosion resistance: Zinc coating helps prevent rusting, particularly in environments exposed to moisture.

- Cost-effective: Galvanized metal is generally more affordable than stainless steel.

- Versatility: It is commonly used in roofing, automotive, appliances, and structural applications.

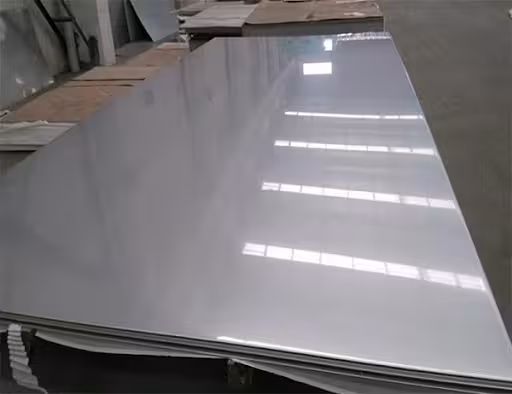

What is Stainless Steel?

Stainless steel, on the other hand, is an alloy composed primarily of iron, chromium, and other elements like nickel and molybdenum. The chromium content in stainless steel forms a protective oxide layer on the surface, preventing rust and corrosion even without a coating. Stainless steel is known for its high strength, durability, and resistance to oxidation, making it a superior choice for many demanding applications.

Key Features of Stainless Steel:

- Corrosion resistance: The chromium oxide layer makes stainless steel highly resistant to corrosion, especially in harsh environments.

- Strength: Stainless steel is stronger and more durable than galvanized sheet metal.

- Aesthetic appeal: It has a shiny, clean appearance, making it ideal for applications where aesthetics matter.

Galvanized Sheet Metal vs. Stainless Steel: A Comparison

The choice between galvanized sheet metal and stainless steel depends on the specific requirements of your project. Below is a comparison of the two materials based on several key factors.

| Factor | Galvanized Sheet Metal | Stainless Steel |

|---|---|---|

| Corrosion Resistance | Good, but zinc coating can wear off over time | Excellent, resistant to corrosion and staining |

| Strength | Moderate | High, stronger than galvanized steel |

| Cost | Low, affordable | Higher cost due to alloy composition |

| Maintenance | Requires periodic maintenance to prevent corrosion | Requires less maintenance due to its natural corrosion resistance |

| Aesthetic Appearance | Dull, matte finish | Shiny, clean, and aesthetically appealing |

| Applications | Suitable for roofing, structural supports, automotive parts | Used in kitchen appliances, medical equipment, high-end construction |

Key Advantages of Galvanized Sheet Metal

Cost-Effective Option

One of the primary benefits of galvanized sheet metal is its cost-effectiveness. The galvanization process is relatively inexpensive compared to the production of stainless steel. This makes galvanized sheet metal an attractive option for budget-conscious projects.

Best for:

- Roofing and siding applications

- Automotive and industrial parts

- Infrastructure projects like bridges and fences

Protection from Corrosion

The zinc coating on galvanized sheet metal provides a protective barrier that helps prevent rust and corrosion. While it’s not as long-lasting as stainless steel, it is highly effective in environments that aren’t constantly exposed to extreme weather conditions.

Best for:

- Mild outdoor exposure

- Areas with occasional exposure to moisture or humidity

Easy to Fabricate

Galvanized sheet metal is easy to work with and fabricate. It can be cut, welded, or molded into various shapes and sizes to suit specific project needs. The manufacturing process is quick and simple, making it ideal for mass production.

Best for:

- Large-scale manufacturing

- Custom metal fabrication

Key Advantages of Stainless Steel

Superior Durability and Strength

Stainless steel offers superior strength compared to galvanized sheet metal. It is more resistant to wear and tear, making it ideal for heavy-duty applications. Stainless steel’s inherent strength ensures it can withstand harsh conditions without compromising its integrity.

Best for:

- Industrial machinery

- Medical equipment

- Architectural elements

Exceptional Corrosion Resistance

Unlike galvanized sheet metal, stainless steel does not rely on a coating for corrosion resistance. The chromium oxide layer on stainless steel naturally protects it from rust, making it suitable for highly corrosive environments such as marine applications.

Best for:

- Food processing equipment

- Chemical processing facilities

- Marine applications

Aesthetic and Long-Term Appeal

Stainless steel’s shiny, clean appearance makes it a preferred choice for visible applications, especially in commercial kitchens, appliances, and architectural features. Its aesthetic appeal, combined with its resistance to corrosion, makes stainless steel a long-lasting option.

Best for:

- Kitchen appliances

- High-end architecture

- Medical and surgical tools

Choosing Between Galvanized Sheet Metal and Stainless Steel

When selecting between galvanized sheet metal and stainless steel, consider the following factors:

Cost Constraints

If your project has a limited budget and corrosion resistance is not a top priority, galvanized sheet metal is the ideal choice. However, if long-term durability and strength are required, stainless steel may be the better investment despite the higher initial cost.

Application Environment

Consider the environment in which the material will be used. If your project is exposed to harsh chemicals, extreme weather conditions, or saltwater environments, stainless steel’s superior corrosion resistance will provide greater long-term benefits.

Strength Requirements

For projects that require superior strength and the ability to withstand heavy wear and tear, stainless steel is the clear choice. However, for lighter applications where strength is less critical, galvanized sheet metal provides adequate support at a lower cost.

Aesthetic Requirements

If the visual appearance of the material is important, stainless steel offers a polished, shiny surface that can enhance the aesthetic appeal of your project. Galvanized sheet metal has a more industrial, matte finish, which may be less appealing for some applications.

Conclusion

Choosing between galvanized sheet metal and stainless steel ultimately depends on your specific needs, including budget, application environment, strength requirements, and aesthetic preferences. Both materials have their advantages, with galvanized sheet metal offering an affordable and effective solution for many applications, while stainless steel excels in high-strength, high-corrosion environments.

This blog provides a comprehensive comparison of galvanized sheet metal and stainless steel, If you need more information, please feel free to contact us.

FAQ

What is galvanized sheet metal?

Galvanized sheet metal is steel coated with a layer of zinc to protect it from rust and corrosion. It is commonly used in industries such as construction, automotive, and manufacturing.

How does stainless steel differ from galvanized sheet metal?

Stainless steel is an alloy of iron and chromium, naturally resistant to corrosion, while galvanized sheet metal has a zinc coating applied for protection against rust. Stainless steel offers higher strength, durability, and corrosion resistance compared to galvanized sheet metal.

Which material is better for outdoor use?

Both materials can be used outdoors, but stainless steel offers superior corrosion resistance and durability in harsh environments such as marine or industrial applications. Galvanized sheet metal is suitable for less demanding outdoor applications but may require periodic maintenance.

Can galvanized sheet metal be used for food-grade applications?

Galvanized sheet metal is generally not recommended for food-grade applications because the zinc coating can potentially react with food. Stainless steel, on the other hand, is the preferred material for food-grade environments due to its non-reactive nature and ease of cleaning.

Is stainless steel more expensive than galvanized sheet metal?

Yes, stainless steel is generally more expensive than galvanized sheet metal due to the higher cost of raw materials and manufacturing processes. However, stainless steel offers long-term durability and reduced maintenance costs, making it a good investment for high-demand applications.