Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

Galvanize pipes, also known as galvanized steel pipes, are steel pipes coated with a protective layer of zinc. This zinc coating provides exceptional corrosion resistance, significantly extending the lifespan of the steel pipe, especially in harsh environments. From plumbing and construction to agriculture and industrial applications, galvanized pipes play a crucial role in various sectors. This comprehensive guide explores everything you need to know about galvanize pipes, including their manufacturing process, types, applications, advantages, and maintenance, subtly highlighting our expertise in providing high-quality steel pipe products.

What are Galvanize Pipes Made Of?

Galvanize pipes start with a base of steel pipe, typically manufactured from carbon steel. The galvanization process then applies a zinc coating. The key components are:

- Steel Core: Provides the structural strength and integrity of the pipe.

- Zinc Coating: Acts as a sacrificial anode, corroding before the steel and protecting it from rust.

The Galvanization Process: How are Galvanize Pipes Made?

The most common method for producing galvanize pipes is hot-dip galvanization. This process involves several key steps:

Cleaning: The steel pipe is thoroughly cleaned to remove any dirt, oil, grease, and mill scale. This ensures proper adhesion of the zinc coating.

Pickling: The pipe is immersed in an acid solution to remove any remaining rust or oxides.

Fluxing: The pipe is dipped in a flux solution, which prepares the surface for the zinc coating.

Hot-Dip Galvanizing: The pipe is immersed in a bath of molten zinc at a high temperature (around 860°F or 460°C). The zinc reacts with the steel surface, forming a series of zinc-iron alloy layers that are metallurgically bonded to the steel.

Cooling and Inspection: The galvanized pipe is cooled and inspected for quality and coating thickness.

Types of Galvanize Pipes

Galvanization is a vital process used to protect steel pipes from corrosion by applying a layer of zinc. While hot-dip galvanization is the most widely used method, there are other techniques that result in different types of galvanized pipes, each suited to specific applications. Here is an overview of the primary types and their characteristics:

Hot-Dip Galvanized Pipes:

This is the most common and effective method of galvanization. In this process, steel pipes are immersed in molten zinc, creating a thick, durable coating. The resulting layer offers excellent corrosion protection, making these pipes ideal for outdoor and industrial applications where exposure to moisture or harsh environments is a concern. Additionally, the thick zinc layer provides enhanced durability, extending the lifespan of the pipes even in demanding conditions. However, the surface may be slightly rough compared to other methods, which is a trade-off for the superior protection it provides.

Electro-Galvanized Pipes:

In this method, an electric current is used to bond a thinner layer of zinc to the steel pipe. While the zinc coating is not as thick as that of hot-dip galvanized pipes, the surface is much smoother and more uniform, giving these pipes an aesthetic advantage. Electro-galvanized pipes are suitable for indoor applications or environments with less exposure to moisture. However, they are less resistant to corrosion compared to hot-dip galvanized pipes, making them less ideal for outdoor or industrial use.

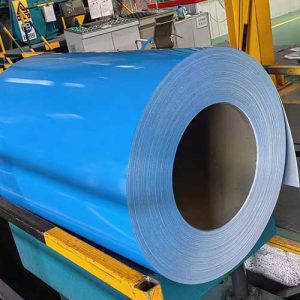

Pre-Galvanized Pipes:

Pre-galvanization involves coating the steel sheet or coil with zinc before it is shaped into a pipe. This method is commonly used for manufacturing lighter-gauge pipes and is typically more cost-effective. While pre-galvanized pipes offer a degree of corrosion resistance, the coating is thinner and may not cover areas where the steel is cut or welded, potentially leaving these spots vulnerable to rust. They are often used in applications where high corrosion resistance is not a critical requirement, such as in construction or indoor settings.

Each type of galvanized pipe has its unique advantages and limitations, making it essential to select the appropriate type based on the intended use, environmental conditions, and budget considerations.

Key Properties and Benefits of Galvanize Pipes

Galvanize pipes offer several significant advantages:

- Excellent Corrosion Resistance: The zinc coating protects the steel from rust and corrosion, even in harsh environments.

- Durability and Long Lifespan: Galvanized pipes can last for decades, reducing the need for frequent replacements.

- Strength and Impact Resistance: The steel core provides high strength and resistance to physical damage.

- Cost-Effectiveness: Although the initial cost may be slightly higher than uncoated steel pipes, the extended lifespan and reduced maintenance make them a cost-effective long-term solution.

- Easy Inspection: The zinc coating provides a visual indication of its integrity. If the zinc is corroded, it is evident.

Applications of Galvanize Pipes in Various Industries

Galvanize pipes are widely used in a variety of applications:

- Plumbing: Water supply lines, drainage systems, and gas lines.

- Construction: Scaffolding, structural supports, and handrails.

- Agriculture: Irrigation systems, livestock watering systems, and fencing.

- Industrial: Chemical processing plants, oil and gas pipelines, and manufacturing facilities.

- Telecommunications: Cable conduits and support structures.

Comparison of Galvanize Pipes with Other Piping Materials

| Feature | Galvanize Pipes | Black Steel Pipes | Copper Pipes | PVC Pipes |

|---|---|---|---|---|

| Corrosion Resistance | Excellent | Poor | Good | Excellent |

| Strength | High | High | Moderate | Low |

| Durability | High | Moderate | High | Moderate |

| Cost | Moderate | Low | High | Low |

| Temperature Resistance | High | High | Moderate | Low |

| Applications | Wide | General purpose | Plumbing | Drainage |

Proper Handling and Maintenance of Galvanize Pipes

To maximize the lifespan of galvanize pipes, proper handling and maintenance are essential:

- Avoid Physical Damage: Protect the zinc coating from scratches and impacts.

- Proper Storage: Store pipes in a dry and well-ventilated area.

- Avoid Contact with Dissimilar Metals: Prevent galvanic corrosion by avoiding direct contact with copper or other dissimilar metals.

- Regular Inspection: Inspect pipes periodically for signs of corrosion or damage.

Our High-Quality Galvanize Pipe Products

As a leading steel pipe manufacturer, we are committed to providing high-quality galvanize steel pipes that meet the most stringent industry standards. Our state-of-the-art facilities and rigorous quality control processes ensure that our products offer superior corrosion resistance, durability, and performance. We offer a wide range of sizes and specifications to meet the diverse needs of our customers.

Conclusion

Galvanized steel pipes offer a cost-effective and reliable solution for applications requiring corrosion protection. Their long lifespan, durability, and strength make them a preferred choice in various industries. As a trusted supplier of quality steel pipe products, we are dedicated to providing our customers with the best galvanize steel pipe solutions to meet their specific needs.

FAQ

What is the primary advantage of using galvanize steel pipes?

The primary advantage is their exceptional corrosion resistance, which significantly extends their lifespan.

How long do galvanize steel pipes typically last?

With proper care, galvanize pipes can last for several decades, often 50 years or more in less corrosive environments.

Can galvanize pipes be used for drinking water?

Yes, galvanize pipes are generally safe for drinking water applications. However, older galvanize pipes may contain lead, so it’s essential to check the age and condition of the pipes.

What is the difference between hot-dip galvanizing and electro-galvanizing?

Hot-dip galvanizing provides a thicker, more durable zinc coating compared to electro-galvanizing.

Can galvanize pipes be welded?

Yes, galvanize pipes can be welded, but special techniques and precautions are necessary to avoid damaging the zinc coating and ensure a strong weld.

Are galvanize pipes more expensive than black steel pipes?

Yes, the initial cost of galvanize pipes is typically higher than black steel pipes due to the galvanization process. However, the extended lifespan and reduced maintenance often make them more cost-effective in the long run.