Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

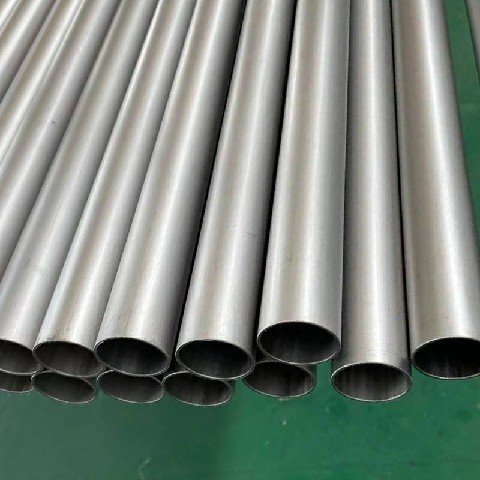

In the world of industrial piping, seamless stainless steel pipe has earned a reputation for its strength, durability, and resistance to corrosion. It is widely used in industries such as oil and gas, automotive, construction, and food processing, owing to its unique qualities that make it ideal for high-pressure and high-temperature applications. This comprehensive guide will walk you through everything you need to know about seamless stainless steel pipe, including its manufacturing process, advantages, applications, and the factors to consider when choosing the right pipe for your project.

What is Seamless Stainless Steel Pipe?

Seamless stainless steel pipe is made from a solid stainless steel billet, which is heated and then pierced to create a hollow tube. Unlike welded pipes, seamless pipes do not have any joints or seams, which makes them stronger and more resistant to internal and external pressure. This manufacturing process gives seamless stainless steel pipes several advantages over other types of piping.

Benefits of Seamless Stainless Steel Pipe

Seamless stainless steel pipes offer several key benefits that make them a popular choice for many applications:

- High Strength:

The absence of a seam gives seamless pipes superior strength. This makes them capable of handling higher pressures and more demanding applications compared to welded pipes. - Durability:

Seamless stainless steel pipe is highly resistant to corrosion, making it suitable for use in harsh environments, including marine, chemical, and high-temperature applications. - Consistent Thickness:

Since seamless stainless steel pipes are manufactured from solid billets, they have a uniform thickness, ensuring consistent performance and reliability. - Versatility:

They can be used in a variety of industries, from construction to food processing, and are often the preferred choice in systems that require high-quality, durable piping. - Reduced Risk of Leaks:

Without seams or welds, seamless stainless steel pipes are less likely to develop leaks over time, providing more secure and long-lasting performance.

Manufacturing Process of Seamless Stainless Steel Pipe

The production of seamless stainless steel pipes involves several key steps:

Step 1: Billet Preparation

A solid billet of stainless steel is prepared, which will serve as the base material for the pipe.

Step 2: Piercing

The billet is heated and pierced to create a hollow tube. This process is known as the rotary piercing process.

Step 3: Elongation

The hollow tube is elongated to the desired length using a process called extrusion or mandrel expansion.

Step 4: Sizing

The pipe is sized to meet specific dimensions using a rotary extrusion process. This ensures that the pipe has a consistent diameter and wall thickness.

Step 5: Heat Treatment and Testing

The pipe is heat-treated to improve its mechanical properties, followed by rigorous testing to ensure it meets industry standards.

Applications of Seamless Stainless Steel Pipe

Seamless stainless steel pipes are used in various industries due to their strength, resistance to corrosion, and versatility. Here are some of the most common applications:

| Industry | Application |

|---|---|

| Oil and Gas | Transportation of oil, gas, and other fluids |

| Chemical Processing | Piping for high-pressure chemical systems |

| Construction | Structural piping in buildings and bridges |

| Food Processing | Food-grade piping for hygiene and safety |

| Automotive | Exhaust systems and engine components |

| Pharmaceuticals | Piping for sterile and regulated environments |

Factors to Consider When Choosing Seamless Stainless Steel Pipe

When selecting seamless stainless steel pipes for your project, there are several important factors to consider:

- Pipe Size and Dimensions:

The pipe’s size, including its diameter and wall thickness, should be chosen based on the requirements of your application. - Material Grade:

Stainless steel comes in various grades, each offering different properties. It is important to choose a grade that aligns with the specific requirements of your environment. Common grades include 304, 316, and 321 stainless steel. - Pressure and Temperature Requirements:

Seamless stainless steel pipes can handle high-pressure and high-temperature conditions. Be sure to select a pipe that meets the demands of your system. - Corrosion Resistance:

If your piping system will be exposed to corrosive environments, selecting a pipe with superior resistance to corrosion is essential. Grades like 316 stainless steel are often used in marine environments due to their high corrosion resistance. - Standards and Certifications:

Ensure that the seamless stainless steel pipes you select meet industry standards such as ASTM A312, ISO 9001, or API 5L. These certifications indicate that the pipes have been tested and meet strict quality standards.

Conclusion

Seamless stainless steel pipes are essential components in many industrial systems due to their durability, resistance to corrosion, and ability to handle high pressure and temperature. Whether used in the oil and gas industry, chemical processing, or construction, seamless stainless steel pipes provide long-lasting and reliable performance. By understanding the manufacturing process, benefits, and considerations involved in choosing seamless stainless steel pipes, you can make informed decisions that enhance the success of your projects.

FAQ

What is the difference between seamless and welded stainless steel pipes?

The main difference is that seamless stainless steel pipes are made from a single billet without welding, whereas welded pipes are made by joining two pieces of metal. Seamless pipes are typically stronger and more durable than welded pipes.

Can seamless stainless steel pipes be used for high-temperature applications?

Yes, seamless stainless steel pipes are highly resistant to high temperatures, making them ideal for use in industries such as chemical processing, power plants, and petrochemical systems.

What are the benefits of using seamless stainless steel pipes in construction?

Seamless stainless steel pipes are strong, durable, and resistant to corrosion, making them an excellent choice for structural applications, particularly in harsh or outdoor environments.

Are seamless stainless steel pipes more expensive than welded pipes?

While seamless stainless steel pipes may be more expensive to manufacture than welded pipes, they often provide superior performance and durability, making them a worthwhile investment in critical applications.

How can I ensure the quality of the seamless stainless steel pipes I purchase?

To ensure quality, buy seamless stainless steel pipes from reputable manufacturers, check for relevant certifications, and request material test reports to confirm that the pipes meet industry standards.