مرحبًا بك في مدونتي!

قبل أن نتعمق في المحتوى، أود أن تنضموا إليّ على منصات التواصل الاجتماعي الخاصة بي حيث أشارك المزيد من الأفكار وأتفاعل مع المجتمع وأنشر التحديثات. إليك كيف يمكنك التواصل معي:

فيسبوك : فيسبوكhttps://www.facebook.com/profile.php?id=61565500692293

والآن، لنبدأ رحلتنا معًا. آمل أن تجدوا المحتوى هنا ثاقباً وجذاباً وقيّماً.

جدول المحتويات

مقدمة

SS (Stainless Steel) steel plates are one of the most versatile materials used in various industries due to their impressive combination of strength, durability, and corrosion resistance. They are primarily used in environments where other materials might degrade due to exposure to harsh elements, chemicals, or extreme temperatures. SS steel plates find their application in many sectors, from construction and automotive industries to food processing and pharmaceuticals.

This comprehensive guide will explore the uses, benefits, properties, and types of SS steel plates. We will delve into why they are so widely used, what industries benefit the most from them, and how to choose the right SS steel plate for your needs. If you are considering using SS steel plates in your project, understanding the key aspects will help ensure you make an informed decision.

ما هو SS Steel Plate?

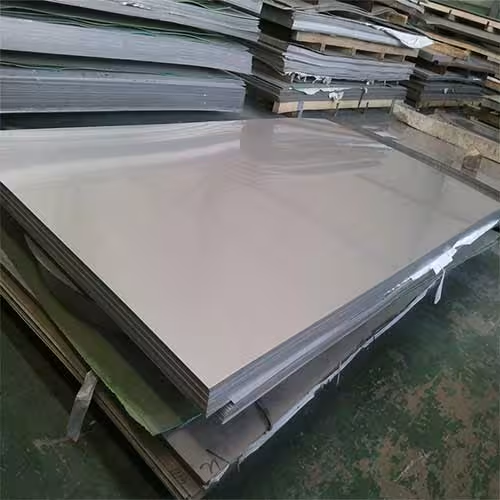

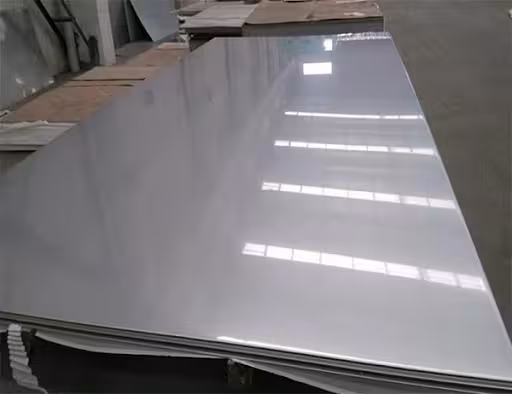

SS steel plate is a flat, solid piece of stainless steel that is commonly used in structural and mechanical applications. Stainless steel is an alloy of iron, chromium, nickel, and other elements that give it excellent corrosion resistance, strength, and toughness. The addition of chromium to the steel forms a passive layer of chromium oxide on the surface, making it resistant to rust and staining.

SS steel plates come in various grades, thicknesses, and sizes, which determine their specific properties, such as resistance to corrosion, heat, and impact. The most common grades of SS steel plates include 304, 316, 410, and 420. These grades are chosen based on the material’s intended use and its exposure to environmental conditions.

Types of SS Steel Plates

There are different types of SS steel plates based on their composition and manufacturing process. Some of the commonly used SS steel plate types are:

- 304 Stainless Steel Plate: This is the most commonly used SS grade, known for its excellent resistance to corrosion and oxidation. It is widely used in food processing, chemical industries, and architectural applications.

- 316 Stainless Steel Plate: This type of SS plate contains molybdenum, which improves its resistance to chloride corrosion. It is ideal for marine environments, chemical processing, and areas with harsh chemicals.

- 410 Stainless Steel Plate: This grade is a martensitic stainless steel that offers high strength and moderate corrosion resistance. It is typically used in aerospace and automotive applications.

- 420 Stainless Steel Plate: Known for its high hardness and ability to be heat-treated, 420 SS plates are often used in knives, surgical instruments, and other high-precision tools.

Factors to Consider When Choosing SS Steel Plates

Selecting the right SS steel plate for your application involves considering several factors. Here are some important elements to keep in mind:

- مقاومة التآكل: The ability to resist rust, oxidation, and corrosion is a crucial factor, especially for applications exposed to moisture or chemicals. SS grades like 304 and 316 offer excellent resistance to corrosion.

- القوة والمتانة: SS steel plates must be strong enough to support heavy loads and withstand harsh environments. Depending on the application, you might need a stronger plate with higher tensile strength.

- القابلية للتشكيل: Some SS steel plates are easier to shape and weld than others. For complex projects that require customization, you may need a plate that offers greater flexibility during fabrication.

- مقاومة درجات الحرارة: In industries where heat resistance is crucial, selecting a heat-resistant SS steel plate is essential. For high-temperature applications, a stainless steel plate with good heat resistance properties is a must.

- Size and Thickness: SS steel plates are available in a variety of sizes and thicknesses, and selecting the right one will depend on the requirements of the project. Thicker plates offer more strength, but they may be harder to work with.

الاستخدامات الشائعة ل SS Steel Plates

SS steel plates are widely used in a variety of industries. Some of the most common uses of SS steel plates include:

صناعة البناء والتشييد

In the construction sector, SS steel plates are used for structural components such as beams, columns, and foundations due to their strength, durability, and resistance to corrosion. They are also used for cladding and roofing in commercial buildings and bridges, where both strength and aesthetic appeal are important.

Automotive and Aerospace Industry

SS steel plates are used in the automotive and aerospace industries for components that must withstand high-stress conditions, extreme temperatures, and corrosive environments. Parts such as exhaust systems, chassis, and engine components are often made from SS steel.

Food and Pharmaceutical Industries

In the food and pharmaceutical industries, cleanliness and corrosion resistance are of paramount importance. SS steel plates are used in manufacturing equipment, storage tanks, and processing machinery because they do not contaminate the products and are easy to clean.

Marine and Chemical Industries

SS steel plates, especially grades like 316, are commonly used in the marine and chemical industries. These plates are resistant to the corrosive effects of saltwater and chemicals, making them ideal for shipbuilding, pipelines, and chemical reactors.

Energy and Power Generation

SS steel plates are also used in power plants and energy generation facilities for components that must withstand high temperatures and harsh operating conditions, such as turbines, heat exchangers, and pressure vessels.

Properties of SS Steel Plates

SS steel plates offer several notable properties that make them suitable for various applications. Here are some of the key characteristics:

مقاومة التآكل

One of the most significant properties of SS steel plates is their resistance to corrosion, which makes them ideal for use in harsh environments. The chromium content in SS plates forms a protective oxide layer that prevents rusting and deterioration.

قوة عالية

SS steel plates are known for their excellent tensile strength, making them suitable for heavy-duty applications where high strength is required. This property ensures that SS plates can handle a wide range of mechanical stresses without breaking or deforming.

مقاومة الحرارة

SS steel plates can withstand high temperatures without losing their structural integrity. This makes them ideal for applications that involve heat exposure, such as in ovens, boilers, and industrial equipment.

Malleability and Weldability

SS steel plates can be easily formed, cut, and welded, allowing them to be used in a wide range of custom designs and applications. This flexibility is particularly important for industries that require specialized or complex parts.

Comparison Table: Types of SS Steel Plates

Here’s a comparison table of some common SS steel plate grades based on key properties:

| الممتلكات | 304 Stainless Steel | 316 Stainless Steel | 410 Stainless Steel | 420 Stainless Steel |

|---|---|---|---|---|

| مقاومة التآكل | ممتاز | ممتاز | معتدل | معتدل |

| القوة | معتدل | عالية | عالية | عالية |

| مقاومة الحرارة | جيد | جيد | عادل | جيد |

| Malleability | جيد | جيد | معتدل | منخفضة |

| الاستخدامات الشائعة | Food processing, architecture | المعالجة البحرية والكيميائية | Automotive, aerospace | Surgical instruments, knives |

الخاتمة

Stainless steel plates are one of the most versatile and durable materials used in a wide range of industries. With their excellent corrosion resistance, strength, heat resistance, and ease of fabrication, they are suitable for applications that require both reliability and performance. By selecting the appropriate grade of SS steel plate, you can ensure that your project meets the necessary structural, environmental, and aesthetic requirements.

When choosing stainless steel plates, it is essential to consider factors such as the specific application, environmental conditions, and required strength. With careful selection, stainless steel plates can provide long-lasting, cost-effective solutions for a wide range of industries.

الأسئلة الشائعة

What is the main difference between 304 and 316 SS steel plates?

The main difference is that 316 stainless steel plates contain molybdenum, which enhances their resistance to chloride corrosion. This makes 316 SS plates more suitable for marine environments or chemical processing, while 304 SS plates are used for general-purpose applications.

Can SS steel plates be used in high-temperature environments?

Yes, SS steel plates are highly resistant to heat and can withstand high temperatures. For extremely high-temperature applications, grades like 310 or 321 stainless steel may be more suitable.

Are SS steel plates suitable for use in food processing?

Yes, SS steel plates, particularly 304 and 316 grades, are commonly used in food processing because of their resistance to corrosion, ease of cleaning, and non-reactive nature.

How do I determine the right SS steel plate for my project?

When selecting SS steel plates, consider the environment in which the plate will be used, the required strength, the temperature range, and the corrosion resistance needed. Different SS grades offer different properties, so choose accordingly.

Are SS steel plates easy to weld?

Yes, SS steel plates are generally easy to weld, especially those made from 304 and 316 grades. However, some grades, like 410 and 420, may require special considerations due to their higher carbon content.