مرحبًا بك في مدونتي!

قبل أن نتعمق في المحتوى، أود أن تنضموا إليّ على منصات التواصل الاجتماعي الخاصة بي حيث أشارك المزيد من الأفكار وأتفاعل مع المجتمع وأنشر التحديثات. إليك كيف يمكنك التواصل معي:

فيسبوك : فيسبوكhttps://www.facebook.com/profile.php?id=61565500692293

والآن، لنبدأ رحلتنا معًا. آمل أن تجدوا المحتوى هنا ثاقباً وجذاباً وقيّماً.

جدول المحتويات

مقدمة

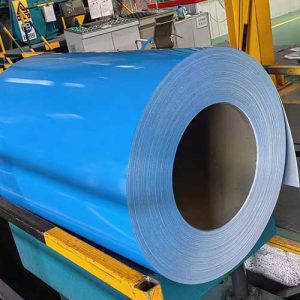

Galvanized steel sheet rolls are an essential component in a wide range of industries, including construction, automotive, and manufacturing. These sheets are made by coating steel with a thin layer of zinc to protect it from corrosion and extend its lifespan. Choosing the right galvanized steel sheet roll can be a daunting task given the variety of types and specifications available in the market. However, understanding the key factors involved in selecting a galvanized steel sheet roll can help you make an informed decision, ensuring the best material for your project needs.

This comprehensive guide will help you navigate the process of selecting the best galvanized steel sheet roll by exploring the key factors, types, and considerations to make when choosing the material for your applications.

Key Factors to Consider When Choosing a Galvanized Steel Sheet Roll

Understanding the Galvanizing Process

Galvanizing is the process of applying a protective zinc coating to steel to prevent rusting. The process typically involves:

- Hot-dip galvanizing: Steel is submerged in molten zinc for a durable and strong coating.

- Electro-galvanizing: Zinc is applied to the steel surface through an electrochemical process, resulting in a thinner, more uniform coating.

The choice between hot-dip and electro-galvanizing depends on the specific requirements of your project, such as corrosion resistance and aesthetic appeal. Hot-dip galvanized steel typically offers superior protection for outdoor applications due to its thicker coating.

Thickness of the Galvanized Steel Sheet Roll

The thickness of the galvanized steel sheet roll determines its strength, durability, and suitability for specific applications. It’s essential to choose the right thickness to match the load-bearing requirements of your project. Common thickness options include:

- Light gauge: Typically ranging from 0.2mm to 0.6mm, suitable for light-duty applications like automotive parts and household appliances.

- Medium gauge: From 0.6mm to 1.5mm, ideal for roofing and construction.

- Heavy gauge: Over 1.5mm, used for high-strength applications like structural support and heavy-duty equipment.

Corrosion Resistance and Coating Weight

Galvanized steel’s primary benefit is its ability to resist corrosion, but the level of protection depends on the zinc coating weight. Coating weight is measured in grams per square meter (g/m²). The higher the coating weight, the better the corrosion resistance. Key factors to consider are:

- G30: Low coating weight (approximately 30g/m²) suitable for indoor or mild conditions.

- G60 and G90: Moderate coating weights suitable for exterior applications or environments with moderate exposure to moisture.

- G180 and G210: High coating weights for environments with high moisture levels or aggressive conditions like coastal areas.

Surface Finish and Appearance

The surface finish of the galvanized steel sheet roll not only impacts its appearance but also its functionality. Some finishes include:

- Spangle finish: A shiny, reflective finish typically found in hot-dip galvanized steel.

- Matt finish: A dull, non-reflective finish preferred for aesthetic applications.

- Smooth finish: A smooth surface ideal for applications where paint or coating adhesion is required.

The finish you select will depend on your intended use. For example, roofing and exterior applications often require a more matte finish to blend with architectural elements.

Application and Environmental Conditions

Consider the specific environmental conditions where the galvanized steel sheet roll will be used. Factors such as exposure to moisture, chemicals, and extreme temperatures will affect the steel’s performance. For example:

- Outdoor construction: Opt for a thicker zinc coating to protect the steel from rain, snow, and humidity.

- Automotive parts: Choose galvanized steel with a smooth finish and moderate coating weight to withstand environmental stress while maintaining structural integrity.

- Agriculture and heavy-duty equipment: Heavy gauge galvanized steel with a high coating weight is ideal for outdoor, exposed applications.

Galvanized Steel Sheet Roll Specifications Comparison

The table below compares various galvanized steel sheet rolls based on different characteristics to help you make an informed decision.

| Steel Sheet Type | Thickness Range (mm) | Coating Weight (g/m²) | Best Use Cases | تشطيب السطح |

|---|---|---|---|---|

| Light Gauge | 0.2mm to 0.6mm | G30 to G60 | Automotive, appliances, and indoor use | Smooth or spangle finish |

| Medium Gauge | 0.6mm to 1.5mm | G60 to G90 | Roofing, construction, fencing | Matt or smooth finish |

| Heavy Gauge | 1.5mm to 4mm | G180 to G210 | Structural support, heavy-duty equipment | Matt finish |

| High-Strength Galvanized | 1mm to 3mm | G180 to G250 | Industrial machinery, marine use | Smooth finish |

Benefits of Using Galvanized Steel Sheet Roll

مقاومة التآكل

The primary advantage of galvanized steel sheet rolls is their resistance to corrosion, extending the lifespan of products and structures. The zinc coating protects the underlying steel from rust and damage caused by environmental exposure.

المتانة والقوة

Galvanized steel is known for its strength and ability to withstand harsh conditions. It is ideal for outdoor structures, automotive parts, and any application requiring high durability.

صيانة منخفضة

The zinc coating on galvanized steel reduces the need for frequent maintenance, saving time and costs in the long run.

قابلية إعادة التدوير

Galvanized steel is fully recyclable, making it an eco-friendly material choice for construction and manufacturing projects.

Aesthetic Flexibility

Galvanized steel sheet rolls are available in various finishes and coatings, providing design flexibility for both functional and decorative uses.

الخاتمة

Choosing the best galvanized steel sheet roll for your project depends on understanding the specific requirements of your application. Key factors to consider include the type of galvanizing process, steel thickness, coating weight, surface finish, and environmental conditions. By carefully evaluating these elements, you can select the ideal galvanized steel sheet roll that will provide long-lasting protection, durability, and functionality.

Whether you are constructing a building, manufacturing automotive parts, or working on heavy-duty equipment, selecting the right galvanized steel sheet roll will ensure the success and longevity of your project.

الأسئلة الشائعة

What is the difference between hot-dip and electro-galvanized steel?

Hot-dip galvanizing involves immersing steel in molten zinc, creating a thicker coating and providing better corrosion resistance. Electro-galvanizing uses an electrical process to apply a thinner, more uniform zinc layer. Hot-dip galvanizing is ideal for more demanding applications.

Can galvanized steel sheet rolls be painted?

Yes, galvanized steel can be painted. However, surface preparation is necessary to ensure good adhesion. A smooth or matte finish is often preferred for painting applications.

How do I determine the right thickness for my galvanized steel sheet roll?

The thickness required depends on the application. Light gauge steel is suitable for indoor uses like appliances, while heavy gauge is necessary for outdoor structures or industrial equipment.

What is the typical lifespan of galvanized steel sheet rolls?

The lifespan of galvanized steel depends on the coating thickness and environmental exposure. In moderate conditions, galvanized steel can last for several decades without significant corrosion.

Can galvanized steel be used in marine environments?

Yes, galvanized steel can be used in marine environments, but it requires a higher coating weight (G180 to G250) for better corrosion resistance in salty air and water.