مرحبًا بك في مدونتي!

قبل أن نتعمق في المحتوى، أود أن تنضموا إليّ على منصات التواصل الاجتماعي الخاصة بي حيث أشارك المزيد من الأفكار وأتفاعل مع المجتمع وأنشر التحديثات. إليك كيف يمكنك التواصل معي:

فيسبوك : فيسبوكhttps://www.facebook.com/profile.php?id=61565500692293

والآن، لنبدأ رحلتنا معًا. آمل أن تجدوا المحتوى هنا ثاقباً وجذاباً وقيّماً.

جدول المحتويات

مقدمة

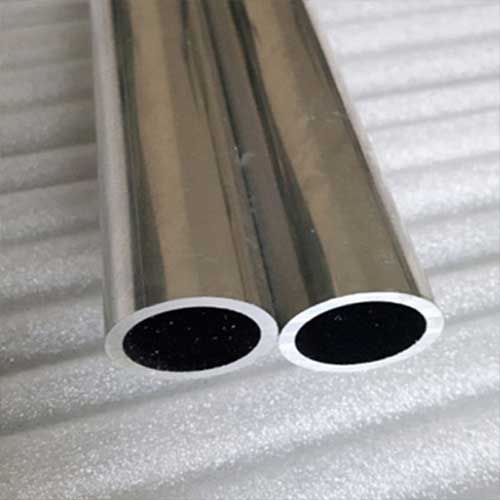

The cold drawn seamless steel tube is a critical component in various industries, offering enhanced mechanical properties and reliability. Unlike traditional welded tubes, cold drawn seamless steel tubes are produced without the use of seams, which ensures they can withstand higher pressures and provide more consistent results. Whether you’re in construction, automotive, or industrial applications, understanding why cold drawn seamless steel tubes are a popular choice can help you make informed decisions. In this article, we will explore the top seven reasons why cold drawn seamless steel tubes stand out in the market.

What is a Cold Drawn Seamless Steel Tube?

Cold drawn seamless steel tubes are manufactured using a process that involves drawing the steel through a mold to reduce its diameter while maintaining its strength. This method provides significant advantages in terms of structural integrity, finish quality, and performance compared to other types of steel tubes. The cold drawing process also improves the surface finish of the tube, making it ideal for precision applications where surface quality matters.

Key Advantages of Cold Drawn Seamless Steel Tube

Higher Strength and Durability

One of the primary reasons to opt for cold drawn seamless steel tube is the superior strength and durability it offers. The drawing process refines the steel structure, enhancing its tensile strength and ability to withstand high-pressure environments. This makes it suitable for critical applications, including those in aerospace, automotive, and heavy machinery industries.

Enhanced Surface Finish

Cold drawn seamless steel tubes have a smoother, more uniform surface compared to other steel tubes. This is especially beneficial for applications where the finish is important, such as in hydraulic systems or precision machinery. The smooth surface ensures better sealing, reduced friction, and improved overall performance.

High Precision and Dimensional Accuracy

Cold drawn seamless steel tubes are known for their exceptional dimensional accuracy. This is achieved through the precise drawing process, which allows for tighter tolerances. This feature is crucial for industries that require parts with specific dimensions, such as in the manufacturing of machinery components, oil and gas pipelines, and structural applications.

Excellent Corrosion Resistance

Due to the high quality of the steel and the lack of welds, cold drawn seamless steel tubes exhibit excellent corrosion resistance. This makes them highly suitable for use in harsh environments, including marine, chemical, and petrochemical industries where corrosion can significantly impact the integrity of equipment.

Consistent Mechanical Properties

Cold drawn seamless steel tubes offer consistent mechanical properties across the entire length of the tube. This is important for industries that rely on predictable performance, as the material exhibits uniform strength, elongation, and hardness throughout the product.

Applications of It

Cold drawn seamless steel tubes are used in a wide variety of applications. These tubes can be found in industries ranging from construction to automotive, as well as in highly specialized sectors like aerospace and energy. Some common uses include:

- Hydraulic systems and equipment

- Automotive components

- Structural elements in buildings and bridges

- Oil and gas pipelines

- Medical devices and equipment

Key Considerations When Choosing It

Tube Size and Tolerances

Before selecting a cold drawn seamless steel tube, it’s essential to consider the size requirements and the precision of the tolerances needed for your specific application. With their precise manufacturing process, these tubes can be produced to meet the exact specifications, but careful planning is required to ensure they meet your needs.

Material Grades and Standards

Different industries may require cold drawn seamless steel tubes to meet specific material grades or standards. Be sure to select tubes that conform to relevant international standards, such as ASTM, EN, or ISO standards, to ensure the material’s quality and suitability for your application.

Table: Properties

| الممتلكات | الوصف |

|---|---|

| التركيب المادي | Primarily carbon steel, stainless steel, alloy steel, etc. |

| القوة | High tensile strength and resistance to pressure |

| تشطيب السطح | Smooth, uniform finish for better performance |

| مقاومة التآكل | Excellent due to lack of seams and consistent material quality |

| Dimensional Tolerance | Tight tolerances for precision applications |

| التطبيقات | Automotive, aerospace, construction, oil & gas, machinery |

الخاتمة

Cold drawn seamless steel tubes offer a range of benefits that make them a top choice in various industrial applications. From superior strength and durability to excellent surface finishes and high precision, these tubes provide the performance and reliability that many industries require. Whether you’re working in manufacturing, energy, or infrastructure, cold drawn seamless steel tubes can offer the performance you need for demanding applications.

الأسئلة الشائعة

What is the main difference between them and welded steel tubes?

Cold drawn seamless steel tubes are made without seams, while welded tubes are formed by welding together edges of a steel strip. This results in cold drawn seamless steel tubes having superior strength, reliability, and uniformity.

How do I determine the correct size of it?

The size of a cold drawn seamless steel tube should be determined by the specific application requirements, such as the pressure, temperature, and load the tube will withstand. Consulting with a supplier can help in selecting the appropriate size and tolerance.

Are these more expensive than other types?

Yes, cold drawn seamless steel tubes generally cost more due to the complexity of the manufacturing process, but the investment pays off in terms of their superior performance and longevity.

Can cold drawn seamless steel tubes be used in high-pressure applications?

Yes, due to their high strength and resistance to internal pressure, cold drawn seamless steel tubes are ideal for high-pressure applications such as hydraulic systems and gas pipelines.