Oil Casing

Oil Casing

Oil casing is a steel pipe used to support the well wall of oil and gas wells.

Oil Casing

Features

- High strength: able to withstand the pressure and tensile force of the formation to ensure the stability of the well wall.

- Good sealing: prevent leakage of formation fluids and protect groundwater resources and the environment.

- Corrosion resistance: in the harsh environment underground, it has a certain corrosion resistance and prolongs the service life.

- High dimensional accuracy: easy to install and connect, ensuring the sealing between casings.

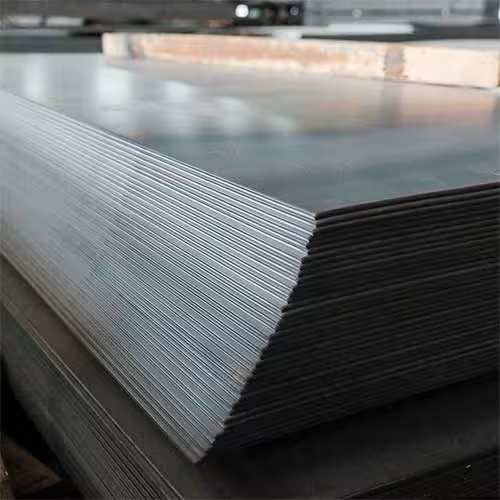

Production process

Usually produced by hot rolling or cold drawing process. The production process includes billet heating, perforation, rolling, sizing, heat treatment, thread processing and other links.

Application field

Oil Casing is mainly used in oil and natural gas extraction industries.

Selection precautions

- Material selection: select suitable steel materials such as carbon steel, alloy steel, etc. according to the formation conditions and mining requirements.

- Specifications and dimensions: select suitable specifications and dimensions such as outer diameter, wall thickness, length, etc. according to the well diameter and mining depth.

- Thread type: Select the appropriate thread type according to the connection method and usage requirements, such as API standard thread, special thread, etc.

- Quality inspection: Check the surface quality, dimensional accuracy, mechanical properties, thread quality and other indicators of the casing to ensure compliance with relevant standards and requirements.

- Manufacturer: Select a manufacturer with good reputation, advanced production technology and strict quality control to ensure product quality and after-sales service.

Reviews

There are no reviews yet.