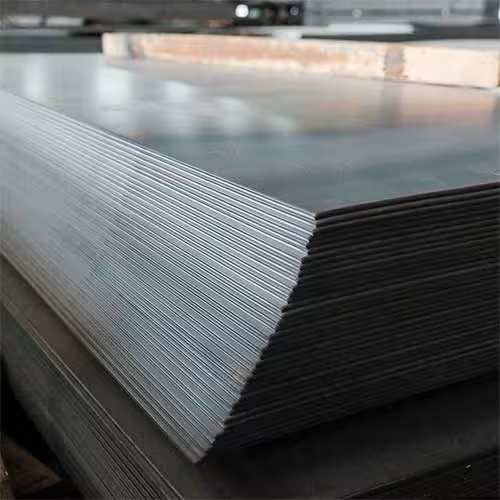

Precision Tube

Precision Tube

Precision tube is a kind of tube with high-precision size and good surface quality.

Precision Tube

Features

- High dimensional accuracy: The outer diameter, wall thickness and other dimensional tolerances of precision tubes are small, which can meet the high-precision use requirements.

- Good surface quality: The outer surface is smooth, without obvious scratches, pits and other defects, and the inner surface roughness is low, which is conducive to the transportation of fluids.

- Excellent mechanical properties: It has high strength, hardness and toughness, and can withstand certain pressure and impact.

- Good corrosion resistance: According to different materials and use environments, precision tubes can have good corrosion resistance.

- Strong machinability: It can be cut, welded, bent and other processing methods to meet different installation and use requirements.

Production process

It is usually produced by cold drawing, cold rolling, fine rolling and other processes. During the production process, various process parameters such as deformation, temperature, speed, etc. need to be strictly controlled to ensure product quality.

Application field

- Machinery manufacturing: used to manufacture various precision mechanical parts, such as hydraulic cylinders, cylinders, transmission shafts, etc.

- Automobile manufacturing: used for the manufacture of key components such as automobile engines and transmissions.

- Aerospace: In the field of aerospace, it is used to manufacture aircraft engine parts, spacecraft structural parts, etc.

- Electronic appliances: used to manufacture housings and radiators of electronic components.

- Medical equipment: used to manufacture medical devices, medical catheters, etc.

Selection considerations

- Material selection: According to the use environment and requirements, select suitable materials, such as carbon steel, alloy steel, stainless steel, etc.

- Dimensional accuracy: According to specific use requirements, select precision tubes that meet the dimensional accuracy standards.

- Surface quality: Check whether the surface of the precision tube is smooth and defect-free, and whether the inner surface roughness meets the requirements.

- Mechanical properties: Understand the mechanical performance indicators of the precision tube, such as strength, hardness, and toughness, to ensure that the use requirements are met.

- Manufacturer: Select a manufacturer with good reputation, advanced production technology, and strict quality control to ensure product quality and after-sales service.

Reviews

There are no reviews yet.