High Pressure Boiler Tube

High Pressure Boiler Tube

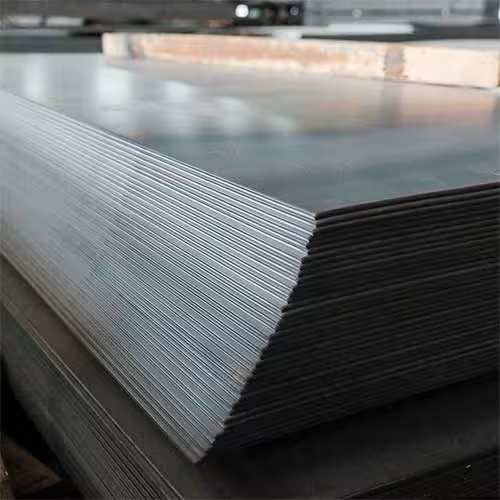

High pressure boiler tube is a high-quality alloy steel seamless steel tube used for manufacturing the heating surface of boilers with high pressure and above.

High Pressure Boiler Tube

Characteristics

- High temperature and high pressure resistance: able to operate stably in high temperature and high pressure environments, and withstand large working pressures and thermal loads.

- Good mechanical performance: It has high strength, toughness, and fatigue resistance, ensuring the safe operation of the boiler.

- Corrosion resistance: In high-temperature water vapor environments, it has a certain degree of corrosion resistance, reducing leakage and damage caused by corrosion.

- High precision dimensions: ensuring the installation accuracy and sealing of the pipeline, reducing the risk of leakage.

Production process

Generally, it is produced using processes such as hot rolling, cold drawing, or hot expansion. The production process includes heating, perforation, rolling, sizing, and heat treatment of steel billets. Among them, the heat treatment process is crucial for the performance of high-pressure boiler tubes, and methods such as normalizing and tempering are usually used to improve the structure and properties of steel.

Application Fields

High Pressure Boiler Tube is mainly used for heating surface pipes of high pressure boiler equipment such as power station boilers and industrial boilers, such as superheater tubes, reheater tubes, water-cooled wall tubes, etc.

Selection precautions

- Material selection: Select the appropriate alloy steel material based on the working pressure, temperature and other parameters of the boiler to ensure that it meets the requirements for use. Common materials for high-pressure boiler tubes include 20G, 12Cr1MoVG, 15CrMoG, etc.

- Specifications and dimensions: According to the boiler design requirements, select appropriate specifications and dimensions such as outer diameter, wall thickness, length, etc. to ensure compatibility with the boiler equipment.

- Quality inspection: Check the surface quality, dimensional accuracy, mechanical properties, metallographic structure and other indicators of the steel pipe to ensure compliance with national standards and relevant technical specifications. Quality inspection can be conducted through visual inspection, non-destructive testing, physical and chemical testing, and other methods.

- Manufacturer: Choose manufacturers with good reputation, advanced production technology, and strict quality control to ensure product quality and after-sales service. You can refer to the manufacturer’s qualification certificate, production equipment, testing methods, and other aspects for selection.

Reviews

There are no reviews yet.