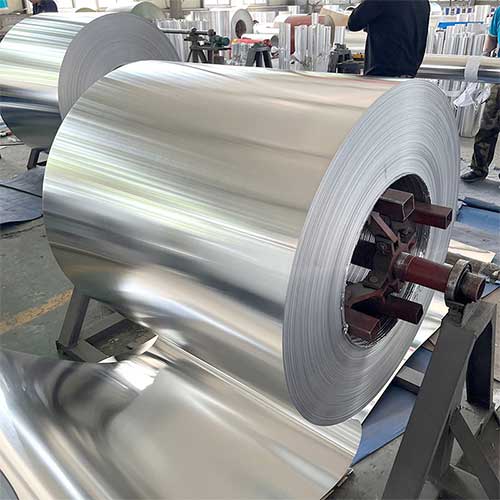

Aluminum Coil

Aluminum Coil

Aluminum coil is a rolled material processed from aluminum.

Aluminum Coil

Characteristics

- Lightweight: The low density of aluminum makes aluminum coils lightweight and easy to handle and transport.

- Corrosion resistance: Aluminum forms a dense oxide film in air, which has good corrosion resistance.

- Easy to process: Multiple processing methods such as cutting, stamping, bending, etc. can be used to meet different application needs.

- Aesthetics: The surface can be treated with various treatments such as anodizing, spraying, etc., which have good decorative properties.

- Good thermal and electrical conductivity: It has application value in some specific fields.

Production process

Mainly produced through rolling process. After heating the aluminum ingot, it is subjected to multiple rolling processes to gradually reduce its thickness and finally rolled into a coil shape.

Application Fields

- In the field of architecture: used for building curtain walls, roofs, ceilings, etc., with good decorative effects and durability.

- Transportation: such as used in automobile manufacturing for body panels, interior parts, etc; It is also widely used in rail transit.

- Electronic appliances: can be used to make components such as heat sinks and casings.

- Packaging industry: used for making cans, food packaging, etc.

Selection precautions

- Alloy types: Different aluminum alloys have different performance characteristics, and the appropriate alloy should be selected according to specific applications.

- Thickness and width: Determine the required aluminum coil thickness and width specifications based on actual needs.

- Surface quality: Check whether the surface of the aluminum coil is flat, smooth, and free of defects such as scratches and oxidation.

- Manufacturer: Choose manufacturers with good reputation and advanced production technology to ensure product quality and after-sales service.

Reviews

There are no reviews yet.