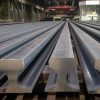

Track Steel

Track Steel

Rail steel, also known as rail, is a special steel used for railway tracks.

Track Steel

Characteristics

1. High strength: Track Steel can withstand the huge weight of the train and the impact force generated during operation.

2. High wear resistance: ensure that it is not easy to wear during long-term use and extend the service life.

3. Good toughness: not easy to break when withstanding impact and vibration.

4. Precise size and shape: ensure the flatness and stability of the track and ensure the safety of train driving.

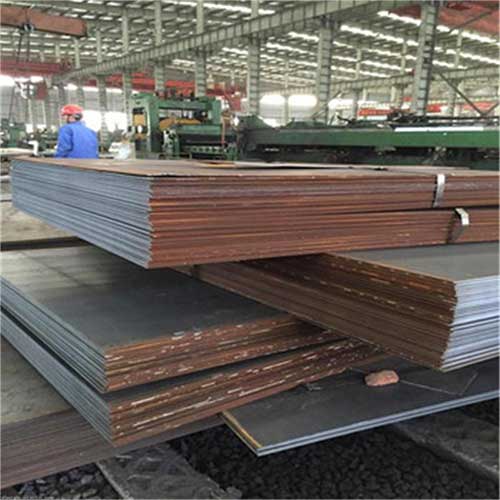

Production process

Usually produced by hot rolling process. After the steel billet is heated to high temperatures, it is rolled through a rolling mill into rails of specific shapes and sizes. Strict quality control is also required during the production process, including chemical composition analysis, mechanical property testing, dimensional accuracy testing, etc.

Application fields

Track Steel is mainly used in railway track construction, including high-speed railways, conventional railways, urban rail transit, etc.

Things to note when choosing

1. Model specifications: Select the appropriate rail model according to the design requirements and usage conditions of the railway, such as different rail weights, lengths, etc.

2. Quality standards: Choose rail products that meet national standards or international standards to ensure reliable quality. Check the surface quality of the rails. There should be no obvious defects such as cracks, inclusions, scratches, etc.

3. Manufacturer: Choose a manufacturer with good reputation and advanced production technology to ensure product quality and after-sales service. At the same time, attention should be paid to the manufacturer’s production capacity and supply capacity to ensure that project needs can be met on time.

Reviews

There are no reviews yet.