Galvanized Coil

Galvanized Coil

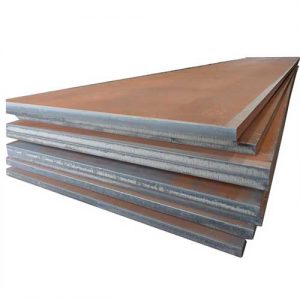

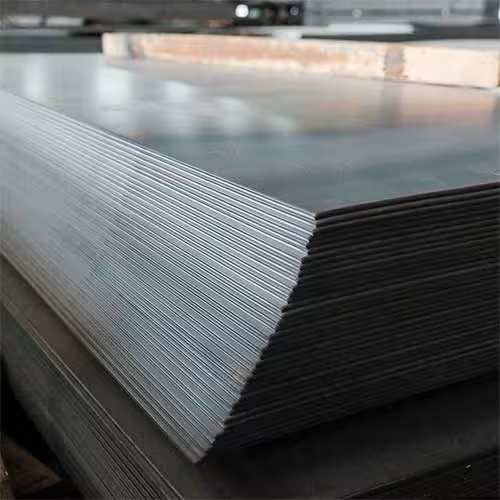

Galvanized coil is a thin steel plate that is immersed in a molten zinc bath to adhere a layer of zinc to its surface.

Galvanized Coil

Characteristics

- Excellent anti-corrosion performance: The zinc layer can effectively prevent the steel plate from being oxidized and corroded, extending its service life.

- Good surface quality: The surface after galvanizing is smooth and flat, with a good appearance.

- Good processing performance: it can be processed in various processing methods such as shearing, bending, and stamping.

- High strength: able to withstand a certain amount of pressure and weight.

Production process

There are mainly two types: hot-dip galvanizing and electro-galvanizing. Hot-dip galvanizing is to immerse the steel plate in molten zinc liquid so that the zinc layer adheres to the surface of the steel plate; electro-galvanizing is to deposit zinc ions on the surface of the steel plate through electrolysis.

Application fields

- Construction field: used on roofs, walls, ventilation ducts, etc.

- Automobile manufacturing: used for automobile body, chassis and other components.

- Home appliance industry: such as refrigerators, washing machines, etc. casings.

- Industrial manufacturing: used to manufacture various containers, shelves, steel structures, etc.

Things to note when choosing

- Zinc layer thickness: The greater the zinc layer thickness, the better the anti-corrosion performance. Generally speaking, the zinc layer thickness of hot-dip galvanized coils is between 60-275g/m².

- Surface quality: Check the surface for scratches, rust spots, zinc tumors and other defects.

- Dimensional accuracy: Choose the appropriate thickness, width and length according to actual needs.

- Manufacturer: Choose a manufacturer with good reputation and reliable quality to ensure product quality.

Reviews

There are no reviews yet.