Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

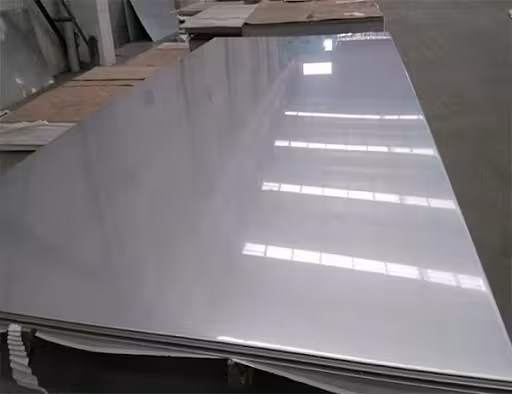

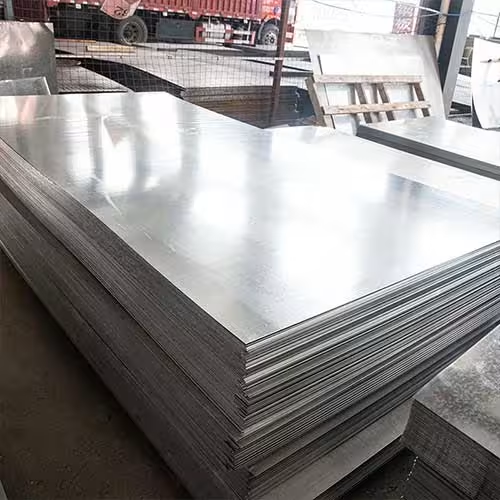

In today’s industrial landscape, materials that combine strength, longevity, and corrosion resistance are in high demand. One of the most widely used materials in this context is the metal sheet galvanized. But what exactly is a metal sheet galvanized, and why has it become so essential in construction, manufacturing, and infrastructure development?

A metal sheet galvanized refers to a steel or iron sheet that has undergone a process called galvanization, where a layer of zinc is applied to protect the metal from rust and corrosion. This layer acts as a shield against environmental factors such as moisture, chemicals, and weather exposure. The galvanization process enhances the durability, performance, and lifespan of the base metal, making it a cost-effective and reliable solution across various industries.

Understanding the properties and applications of metal sheet galvanized products is crucial for anyone involved in engineering, architecture, or maintenance planning. This article will explore everything you need to know about metal sheet galvanized materials, including how they are made, where they are used, and how to maintain them for long-term performance.

What Is Galvanization? The Science Behind Metal Sheet Galvanized

The Galvanization Process in Metal Sheet Galvanized

Galvanization is a method used to coat steel or iron with a thin layer of zinc to protect it from rust. This process is essential for producing a metal sheet galvanized that resists corrosion and offers long-term performance, especially in environments exposed to moisture or salt.

There are three primary methods for creating a metal sheet galvanized:

Hot-Dip Galvanizing for Metal Sheet Galvanized

Hot-dip galvanizing involves immersing the metal into a bath of molten zinc at high temperatures. As the metal reacts with the zinc, a series of zinc-iron alloy layers are formed, creating a strong bond between the coating and the base metal. This method is highly effective for producing thick and durable coatings on metal sheet galvanized materials.

Electro-Galvanizing for Precise Applications

Electro-galvanizing applies zinc to the surface of the metal sheet galvanized using an electric current. This process results in a thinner, more uniform coating, which is ideal for applications requiring smooth finishes or tighter dimensional tolerances, such as in electronics or automotive body panels.

Pre-Galvanizing for Continuous Production

Pre-galvanizing is done before the final forming of the metal, typically on a production line where large coils of metal are cleaned and coated continuously. It’s an efficient method for producing high volumes of metal sheet galvanized, particularly for construction and framing applications.

Each of these techniques plays a significant role in tailoring the properties of metal sheet galvanized products for different industrial and environmental requirements.

Benefits of Using Metal Sheet Galvanized

Using metal sheet galvanized materials brings numerous advantages that contribute to its widespread adoption in various sectors. Here are the main benefits:

Superior Corrosion Resistance

One of the primary reasons metal sheet galvanized is preferred is its excellent resistance to corrosion. The zinc layer protects the base metal from oxygen and moisture, preventing the rusting process. Even if the surface gets scratched, the zinc continues to provide protection through a process called galvanic action.

Extended Service Life

A metal sheet galvanized can last decades, depending on the thickness of the zinc coating and environmental exposure. In general, these sheets can perform for 20 to 70 years without significant degradation, especially in rural or mild environments.

Cost-Effectiveness Over Time

Though initially more expensive than untreated steel, metal sheet galvanized provides significant savings over time due to its low maintenance requirements and long service life. This makes it an economical choice for both small- and large-scale projects.

Sustainability and Recyclability

Galvanized steel is 100% recyclable. The zinc and steel can both be recovered and reused without loss of quality, contributing to sustainable construction and manufacturing practices.

Broad Industry Versatility

From infrastructure to appliances, the use of metal sheet galvanized spans nearly every sector. Its versatility, combined with its performance, makes it a highly adaptable material.

Common Applications of Metal Sheet Galvanized

Metal sheet galvanized products are found in nearly every industry due to their functional properties and durability. Below are some of the most common applications.

Construction Industry and Metal Sheet Galvanized

In the building and construction sector, metal sheet galvanized materials are used extensively for:

- Roofing and siding

- Structural framing

- HVAC ductwork

- Gutters and drainage systems

- Stair treads and balconies

The corrosion-resistant nature of metal sheet galvanized makes it ideal for both indoor and outdoor applications.

Automotive Industry Applications

Metal sheet galvanized is also a staple in the automotive industry. It is used to manufacture:

- Car body panels

- Undercarriages

- Exhaust systems

- Chassis parts

Its ability to resist rust significantly extends vehicle life and improves safety.

Agricultural and Rural Usage

In farming and rural infrastructure, the use of metal sheet galvanized includes:

- Storage silos

- Fencing

- Irrigation equipment

- Animal enclosures

- Barn roofing

It’s chosen for its reliability in environments with high humidity, dirt, and water exposure.

Electrical and Appliance Manufacturing

Many household and industrial appliances use metal sheet galvanized due to its conductivity and durability. Applications include:

- Electrical boxes

- Air conditioning units

- Refrigerator panels

- Washing machine frames

The zinc coating also provides added safety in electrical systems by resisting wear and tear.

Comparison Table: Metal Sheet Galvanized vs Other Sheet Metals

Below is a comparison of metal sheet galvanized against other commonly used sheet metals in industrial applications:

| Feature | Metal Sheet Galvanized | Aluminum Sheet | Stainless Steel Sheet |

|---|---|---|---|

| Corrosion Resistance | Excellent | Good | Very Good |

| Weight | Medium | Light | Heavy |

| Cost | Moderate | Higher | Highest |

| Weldability | High | Low | Moderate |

| Longevity in Outdoor Conditions | Very High | Moderate | Very High |

| Recyclability | Yes | Yes | Yes |

| Surface Coating Required | No | Usually Yes | No |

This table illustrates why metal sheet galvanized is often selected for projects requiring cost-efficient durability and reliable performance in corrosive environments.

Maintenance Tips for Metal Sheet Galvanized

Proper maintenance can significantly extend the lifespan and performance of metal sheet galvanized materials. Here are some key tips:

- Regular cleaning: Periodically wash the surface to remove dirt, grime, and chemical residues.

- Avoid mechanical damage: Handle with care during transportation and installation to prevent scratches.

- Check for pooling water: Ensure that the structure allows proper drainage to prevent corrosion hotspots.

- Apply protective paint when necessary: In highly corrosive environments, painting over the zinc layer adds another level of protection.

- Inspect annually: Conduct regular inspections to identify wear, damage, or corrosion early.

Conclusion

Choosing metal sheet galvanized materials is a strategic decision that offers both immediate and long-term benefits. It combines strength, resilience, and affordability, making it ideal for almost every industrial or architectural application.

Whether you are building a skyscraper, manufacturing a vehicle, or designing an irrigation system, metal sheet galvanized provides the reliability you need. Its ability to withstand environmental challenges, resist rust, and remain structurally sound over time is unmatched by many other materials.

With the growing emphasis on sustainable building and cost-efficient infrastructure, the demand for metal sheet galvanized continues to rise. Investing in this material means investing in quality, longevity, and performance.

FAQ

What is a metal sheet galvanized made of?

A metal sheet galvanized is typically made from steel or iron coated with a layer of zinc to protect it from corrosion.

How long does metal sheet galvanized last?

Depending on environmental exposure and thickness of the coating, metal sheet galvanized can last between 20 to 70 years.

Can metal sheet galvanized be painted?

Yes, painting is possible with proper surface preparation, especially in highly corrosive environments.

Is metal sheet galvanized safe for food contact?

Certain types are safe for indirect food contact, but it’s essential to use certified food-grade materials for direct contact.

What is the thickness range of metal sheet galvanized?

These sheets typically range from 0.25 mm to several millimeters in thickness, depending on application requirements.