Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

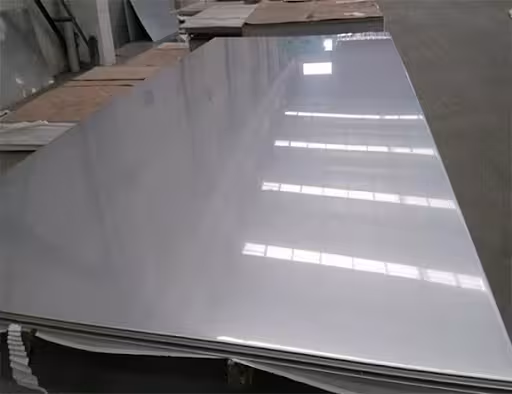

Steel plate thickness plays a crucial role in various industries, including construction, shipbuilding, and manufacturing. Choosing the right steel plate thickness ensures durability, structural integrity, and performance under different conditions.

In this guide, we will explore the fundamentals of steel plate thickness, including measurement methods, industry standards, and applications. A detailed comparison table will help you understand how different thicknesses are used across industries. By the end of this article, you will have a complete understanding of how to select the best steel plate thickness for your needs.

Understanding Steel Plate Thickness

What Is Steel Plate Thickness?

Steel plate thickness refers to the depth of a steel sheet or plate, which influences its weight, strength, and load-bearing capacity. It is typically measured in millimeters (mm) or inches, with thickness values ranging from very thin sheets to extremely thick plates used in heavy-duty applications.

How Is Steel Plate Thickness Measured?

There are several ways to measure steel plate thickness, including:

- Gauge measurement – A traditional system where numbers are assigned to different thicknesses. However, gauge values vary depending on the type of metal.

- Caliper measurement – A precise method using a caliper tool to determine the plate’s thickness.

- Ultrasonic thickness testing – A non-destructive testing technique for measuring thick steel plates.

- Micrometer measurement – A highly accurate method used for fine measurements in specialized industries.

Industry Standards for Steel Plate Thickness

Common International Standards

Steel plates must meet specific industry standards to ensure consistency in thickness and performance. Some widely recognized standards include:

- ASTM (American Society for Testing and Materials) – A globally used system that defines steel plate thickness based on industrial applications.

- EN (European Norms) – The standard for steel plates used across Europe.

- JIS (Japanese Industrial Standards) – A classification system followed in Japan for steel plate materials.

- GB (Guobiao Standards, China) – The official Chinese standard for steel manufacturing.

These standards classify steel plate thickness based on its intended use, ensuring compliance with structural and safety requirements.

Applications of Steel Plate Thickness

Different thicknesses of steel plates serve distinct purposes across industries. Below are some typical applications based on thickness categories:

- Thin steel plates (1mm – 5mm) – Used in automotive body panels, roofing sheets, and lightweight structures.

- Medium steel plates (5mm – 20mm) – Common in construction, shipbuilding, and pressure vessels.

- Thick steel plates (20mm – 100mm) – Used in heavy equipment, bridges, and industrial tanks.

The table below provides a detailed comparison of steel plate thickness across industries.

Comparison of Steel Plate Thickness Applications

| Steel Plate Thickness | Industry | Common Applications |

|---|---|---|

| 1mm – 5mm | Automotive, Roofing | Car body panels, metal roofing sheets, lightweight structures |

| 5mm – 10mm | Construction, Shipbuilding | Structural reinforcements, marine vessels, storage tanks |

| 10mm – 20mm | Heavy Equipment, Bridges | Load-bearing components, structural beams, industrial platforms |

| 20mm – 50mm | Pressure Vessels, Industrial Machinery | Boiler tanks, industrial pipes, mining equipment |

| 50mm – 100mm | Defense, Offshore Engineering | Armor plating, offshore drilling platforms, nuclear reactors |

This table serves as a quick reference for selecting the right steel plate thickness for specific applications.

Factors to Consider When Selecting Steel Plate Thickness

Load-Bearing Capacity

The required thickness of a steel plate depends on the load it must support. Structural applications such as bridges and buildings require thicker plates to ensure safety and stability.

Corrosion Resistance

For applications exposed to moisture, chemicals, or extreme weather, choosing a corrosion-resistant steel plate thickness is essential. Options such as galvanized or stainless steel improve durability.

Fabrication and Welding Needs

Different steel plate thickness levels require specific welding and fabrication techniques. Thinner plates are easier to cut and shape, while thicker plates require specialized tools for processing.

Weight and Transport Considerations

Thicker steel plates add more weight to a project, affecting transportation and installation costs. Balancing thickness with structural requirements is necessary for optimizing efficiency.

Cost Efficiency

While thicker plates provide better strength, they are also more expensive. Industries must evaluate budget constraints while selecting steel plate thickness that meets performance requirements.

Conclusion

Choosing the right steel plate thickness is critical for ensuring strength, durability, and cost-effectiveness in construction, manufacturing, and engineering projects. Understanding industry standards, application requirements, and fabrication considerations helps in selecting the best material for the job.

By analyzing factors such as load capacity, corrosion resistance, and weight constraints, businesses can optimize their use of steel plate thickness for improved performance and efficiency.

FAQ

What is the standard thickness of a steel plate?

Standard thicknesses vary based on industry needs, ranging from 1mm to 100mm. Common thicknesses include 5mm, 10mm, 20mm, and 50mm.

How do I determine the right steel plate thickness for my project?

Consider load-bearing requirements, environmental conditions, and industry standards such as ASTM or EN classifications.

Does steel plate thickness affect welding?

Yes, thicker steel plates require higher heat input and specialized welding techniques, while thinner plates are easier to weld but may need reinforcement.

What industries use thick steel plates?

Thick steel plates are used in industries such as construction, shipbuilding, defense, and heavy machinery manufacturing.

How does steel plate thickness impact structural integrity?

Thicker plates provide enhanced stability, making them suitable for bridges, pressure vessels, and industrial applications requiring high strength.