Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

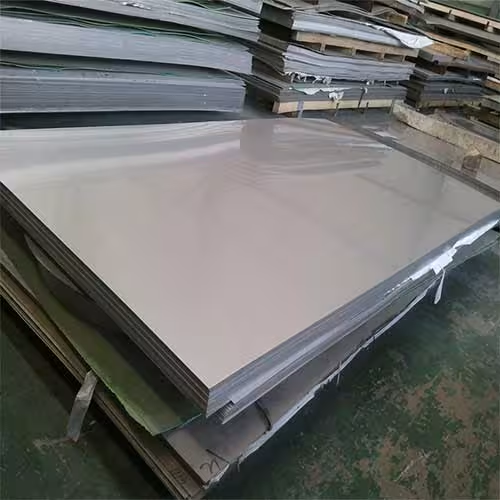

Steel metal plates are one of the most versatile materials used across various industries, from construction and manufacturing to automotive and shipbuilding. These plates are available in different types, thicknesses, and grades, making them suitable for a wide range of applications. Whether used for structural reinforcement, machinery components, or decorative purposes, steel metal plates provide durability, strength, and resistance to wear and corrosion.

This article explores the different types of steel metal plates, their properties, and their applications in various industries. By understanding these factors, you can make an informed decision when selecting the right steel plate for your project.

What Are Steel Metal Plates?

Steel metal plates are flat sheets of steel that are manufactured in different thicknesses, sizes, and compositions. These plates serve as essential materials in construction, manufacturing, transportation, and other industries. They are typically made from carbon steel, stainless steel, or alloy steel, each offering specific advantages based on their composition.

Steel metal plates are produced through a variety of processes, including hot rolling and cold rolling, to meet different mechanical and structural requirements. They can be cut, welded, and formed into specific shapes to suit a variety of industrial applications.

Types of Steel Metal Plates

Carbon Steel Plates

Carbon steel plates are among the most commonly used steel plates due to their affordability and strength. They contain varying amounts of carbon, which determines their hardness and toughness. These plates are widely used in construction, shipbuilding, and industrial machinery.

Key Features:

- High strength and durability

- Cost-effective

- Available in different grades for specific applications

Applications:

- Structural components in buildings and bridges

- Ship hulls and offshore structures

- Pressure vessels and boilers

Stainless Steel Plates

Stainless steel plates contain chromium, which gives them excellent corrosion resistance. These plates are commonly used in industries where exposure to moisture, chemicals, or extreme temperatures is a concern.

Key Features:

- High resistance to rust and corrosion

- Suitable for food, medical, and marine applications

- Available in different finishes for aesthetic and functional purposes

Applications:

- Food processing and pharmaceutical equipment

- Chemical and marine industries

- Architectural and decorative applications

Alloy Steel Plates

Alloy steel plates are made by adding elements such as nickel, chromium, molybdenum, and vanadium to improve specific properties. These plates offer superior strength, wear resistance, and impact resistance.

Key Features:

- Enhanced strength and hardness

- Improved resistance to wear and impact

- Ideal for heavy-duty applications

Applications:

- Military and defense equipment

- Heavy machinery and mining equipment

- Automotive and aerospace components

Galvanized Steel Plates

Galvanized steel plates are coated with a layer of zinc to prevent rust and corrosion. These plates are commonly used in outdoor structures and environments where protection against moisture is essential.

Key Features:

- Superior rust and corrosion resistance

- Long-lasting performance in harsh environments

- Low maintenance requirements

Applications:

- Roofing and siding for buildings

- Outdoor structural components

- Automotive body parts

Comparison of Different Steel Metal Plates

The table below provides a comparison of the different types of steel metal plates based on their characteristics and typical applications.

| Type of Steel Metal Plate | Strength | Corrosion Resistance | Common Applications |

|---|---|---|---|

| Carbon Steel Plate | High | Low | Construction, shipbuilding, pressure vessels |

| Stainless Steel Plate | Medium-High | Very High | Food processing, medical, marine industries |

| Alloy Steel Plate | Very High | Medium | Aerospace, mining, heavy machinery |

| Galvanized Steel Plate | Medium | High | Roofing, automotive, outdoor structures |

Applications of Steel Metal Plates

Construction and Infrastructure

Steel metal plates are widely used in construction projects, including buildings, bridges, and infrastructure. Their high strength and durability make them ideal for load-bearing structures and reinforcement components.

Shipbuilding and Marine Industry

The marine industry relies on steel metal plates for ship hulls, offshore platforms, and marine equipment. Corrosion-resistant plates, such as stainless steel and galvanized steel, are preferred in these applications.

Automotive and Aerospace

Steel metal plates play a vital role in automotive and aerospace engineering. They are used in vehicle frames, aircraft components, and protective armor due to their impact resistance and lightweight properties.

Manufacturing and Machinery

Industrial machinery, equipment, and tools are commonly manufactured using steel metal plates. Alloy steel plates are particularly useful in manufacturing due to their high wear resistance and strength.

Conclusion

Steel metal plates are an essential material in numerous industries, offering versatility, strength, and durability. Understanding the different types of steel plates and their applications helps in selecting the right material for a specific project. Whether you need corrosion resistance, high strength, or affordability, steel metal plates provide a solution for various industrial and structural needs.

By considering factors such as plate type, composition, and intended use, you can make an informed choice that ensures efficiency and longevity in your applications.

FAQ

What is the difference between carbon steel and stainless steel plates?

Carbon steel plates are primarily composed of iron and carbon, making them strong but susceptible to rust. Stainless steel plates, on the other hand, contain chromium, which provides excellent corrosion resistance and makes them ideal for environments with high moisture and chemical exposure.

What are the most common applications of steel metal plates?

Steel metal plates are widely used in construction, shipbuilding, automotive, aerospace, manufacturing, and the marine industry. They serve as structural components, protective armor, machinery parts, and corrosion-resistant surfaces.

How do I choose the right steel metal plate for my project?

The selection of a steel metal plate depends on factors such as strength, corrosion resistance, durability, and intended application. For structural purposes, carbon steel plates are commonly used, while stainless steel is preferred for corrosion-resistant applications.

What is the advantage of using galvanized steel plates?

Galvanized steel plates have a protective zinc coating that prevents rust and corrosion, making them ideal for outdoor structures, roofing, and automotive applications. They require less maintenance and have a longer lifespan compared to untreated steel plates.

Can steel metal plates be customized?

Yes, steel metal plates can be customized in terms of size, thickness, surface finish, and coatings. Customization allows them to meet specific project requirements, such as increased durability, weight reduction, or improved corrosion resistance.