Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

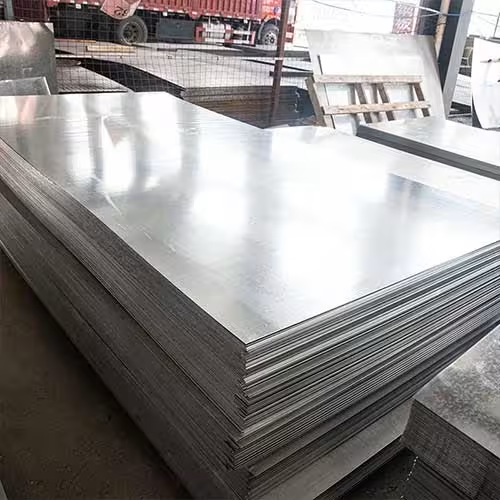

In industries ranging from construction to automotive manufacturing, the need for durable materials is paramount. One such material that has earned a reputation for its robustness and longevity is galvanized steel. Galvanized steel sheets are used in a variety of applications, thanks to their ability to withstand environmental factors and extend the lifespan of products. This blog will explore how galvanized steel sheets improve durability, why they are widely used, and the advantages they bring to various industries.

What is Galvanized Steel?

Before delving into how galvanized steel sheets improve durability, it’s essential to understand what galvanized steel is. Galvanized steel is steel that has been coated with a layer of zinc to protect it from corrosion and rust. The zinc coating acts as a barrier between the steel and the elements, providing enhanced durability.

The process of galvanizing involves immersing steel into molten zinc, which bonds to the surface, creating a hard, protective layer. This protective layer provides several benefits, making galvanized steel a preferred choice in many industries, especially where exposure to moisture or harsh environments is a concern.

Key Benefits of Galvanized Steel Sheets

Galvanized steel sheets are highly valued for their ability to improve the durability of products in various applications. Below are some of the key benefits of using galvanized steel sheets:

- Corrosion Resistance: The zinc coating prevents moisture and other corrosive elements from coming into direct contact with the steel, reducing the risk of rust and corrosion.

- Extended Lifespan: Galvanized steel has a much longer lifespan than untreated steel, especially in environments with high humidity, salt, or other corrosive substances.

- Cost-Effective: Though galvanized steel sheets may cost more upfront, their longevity and reduced maintenance requirements make them a cost-effective solution in the long run.

- Strength and Toughness: Galvanized steel is strong, tough, and resistant to mechanical damage, making it ideal for use in heavy-duty applications.

- Environmentally Friendly: Zinc is a naturally abundant and recyclable material, which makes galvanized steel a more environmentally sustainable option compared to other materials.

Applications of Galvanized Steel Sheets

Galvanized steel sheets are used in a wide range of applications due to their durability. Some of the most common uses include:

Construction Industry

In construction, galvanized steel sheets are used in roofing, siding, and structural components. Their ability to withstand exposure to the elements makes them a top choice for buildings that require long-lasting protection. The coating ensures that the steel remains rust-free even when exposed to rain, snow, or high humidity.

Automotive Industry

The automotive industry benefits greatly from the use of galvanized steel sheets. These sheets are used in car body panels, exhaust systems, and other components that are constantly exposed to moisture, salt, and road debris. The corrosion-resistant properties of galvanized steel enhance the durability of vehicles, allowing them to maintain their structural integrity for a longer period.

Agricultural Equipment

Galvanized steel is commonly used in the manufacturing of agricultural equipment such as silos, storage tanks, and fencing. The protective zinc layer ensures that these products remain resistant to the harsh outdoor conditions and chemical exposure typically found in agricultural settings.

Energy and Utilities

In the energy and utilities sector, galvanized steel sheets are used in the construction of electrical poles, transformers, and pipelines. The corrosion resistance is crucial for ensuring the longevity and safe operation of these critical infrastructures.

Consumer Goods

Galvanized steel is also found in consumer goods such as appliances, home décor items, and furniture. These products benefit from the added strength and corrosion resistance provided by the galvanized coating.

How Galvanized Steel Sheets Improve Durability

Now that we have established what galvanized steel is and its common applications, let’s dive deeper into how galvanized steel sheets specifically improve durability in various industries.

Corrosion Protection and Longevity

One of the primary reasons galvanized steel sheets improve durability is their corrosion-resistant properties. The zinc coating protects the underlying steel from water, air, and chemicals that would otherwise cause rust and corrosion. This corrosion protection is particularly crucial in outdoor environments or industries where products are exposed to the elements.

Galvanized steel’s ability to resist rust means it can endure for decades without the need for frequent repairs or replacements. This makes it an ideal material for industries where maintaining infrastructure and equipment is both costly and time-consuming.

Resistance to Wear and Tear

Galvanized steel sheets are not only resistant to corrosion but also to physical wear and tear. Their toughness and hardness make them durable even when subjected to mechanical stress, such as impact or abrasion. For industries like construction, where materials are frequently exposed to physical damage, galvanized steel provides a durable solution that can withstand rough handling without compromising performance.

Low Maintenance Requirements

The durability of galvanized steel sheets means that they require minimal maintenance over their lifespan. Unlike untreated steel, which may require frequent painting or rust-proofing, galvanized steel needs little attention once it has been installed. This helps reduce overall maintenance costs and extends the life of products and structures made from galvanized steel.

Temperature Resistance

Galvanized steel sheets also offer durability in extreme temperatures. Whether subjected to freezing cold or intense heat, the galvanized coating helps protect the steel from degradation due to temperature extremes. This feature makes it suitable for use in industries that operate in harsh climates or temperature-sensitive environments.

Factors to Consider When Choosing Galvanized Steel Sheets

When selecting galvanized steel sheets for a particular application, there are several factors to consider. These include:

- Thickness: The thickness of the galvanized steel sheet will determine its strength and resistance to mechanical stress. Thicker sheets are typically used in heavy-duty applications.

- Zinc Coating Weight: The weight of the zinc coating affects the level of corrosion protection. Heavier coatings provide better protection but may increase the cost.

- Sheet Size: The size of the steel sheets will depend on the intended application. Larger sheets are needed for larger projects, such as roofing or structural elements.

- Environmental Conditions: The specific environmental conditions the galvanized steel will be exposed to should be considered. For example, products used in coastal areas with high salt content may require thicker zinc coatings for added corrosion protection.

Comparison of Galvanized Steel Sheets vs Other Materials

Here’s a comparison of galvanized steel sheets with other materials commonly used for durability in construction and manufacturing:

| Feature/Material | Galvanized Steel Sheets | Stainless Steel | Aluminum | Plastic |

|---|---|---|---|---|

| Corrosion Resistance | Excellent | Excellent | Moderate | Low |

| Strength | High | Very High | Moderate | Low |

| Durability | Long-lasting | Very Long-lasting | Moderate | Low |

| Maintenance Requirements | Low | Low | Low | High |

| Cost | Moderate | High | Moderate | Low |

| Weight | Moderate | Heavy | Light | Very Light |

| Temperature Resistance | High | Very High | High | Low |

The table shows that while stainless steel offers exceptional strength and longevity, galvanized steel is a more cost-effective solution for applications that don’t require the extreme durability of stainless steel. On the other hand, materials like plastic and aluminum may not offer the same level of protection and may need more maintenance in certain environments.

Conclusion

Galvanized steel sheets are a reliable and durable choice for a wide range of applications, from construction to automotive manufacturing. Their corrosion resistance, low maintenance requirements, and strength make them an ideal material for environments exposed to harsh conditions. By choosing galvanized steel sheets, industries can reduce long-term costs, extend the life of their products, and maintain high-quality standards.

With the wide range of applications and benefits they offer, galvanized steel sheets continue to play a critical role in ensuring the durability and longevity of products and structures across various industries.

FAQ

What is the process of galvanizing steel?

The process of galvanizing steel involves coating the steel with a layer of zinc. This is typically done by immersing the steel in molten zinc, which forms a protective layer that prevents rust and corrosion.

How long does galvanized steel last?

Galvanized steel can last anywhere from 20 to 50 years, depending on environmental conditions and the thickness of the zinc coating. In corrosive environments, such as coastal areas, the lifespan may be shorter.

Is galvanized steel suitable for outdoor use?

Yes, galvanized steel is highly resistant to rust and corrosion, making it an excellent choice for outdoor applications such as roofing, fencing, and construction materials.

Can galvanized steel be painted?

Yes, galvanized steel can be painted, although it requires proper surface preparation to ensure the paint adheres correctly to the zinc coating.

How does galvanized steel compare to stainless steel in terms of durability?

Stainless steel offers superior durability, especially in extremely corrosive environments. However, galvanized steel is more cost-effective and still provides excellent protection against corrosion, making it a great choice for many applications.