Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Thank you very much for reading this blog, I hope you find it helpful.

If you have any questions or would like to discuss how we can help you with your steel needs, please feel free to contact us: Contact Us

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

Wear resistant steel plates are essential materials in industries where equipment is subjected to extreme abrasion and impact. Their primary purpose is to enhance the durability of machinery, reducing downtime and maintenance costs. Choosing the right wear resistant steel plate can greatly improve the performance of your operations, whether in mining, construction, or manufacturing.

This guide explores the properties, benefits, and applications of wear resistant steel plates, helping you make informed decisions for your specific needs.

What Is a Wear Resistant Steel Plate?

Definition

A wear resistant steel plate is a type of steel designed to withstand abrasion, impact, and harsh environments. It is commonly used in industries where machinery encounters abrasive materials, such as mining, construction, and transportation.

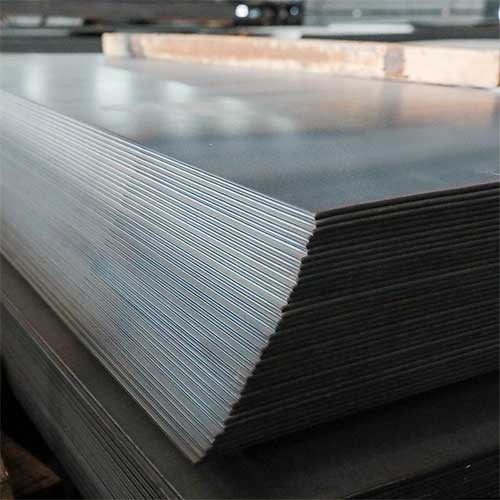

Key Properties

- High hardness, typically ranging from 400 HBW to 600 HBW.

- Excellent toughness to absorb impact.

- Exceptional resistance to wear and abrasion.

- Good formability for cutting, bending, and welding.

Factors to Consider When Choosing a Wear Resistant Steel Plate

Application Requirements

The application determines the level of hardness and toughness needed. For example, mining equipment often requires higher hardness, while construction machinery may need a balance of toughness and abrasion resistance.

Material Grade

Different grades offer varying levels of wear resistance:

- AR400 is suitable for moderate wear.

- AR500 is ideal for high abrasion conditions.

- AR600 is designed for extreme wear environments.

Thickness

The plate’s thickness impacts its durability and weight. Thicker plates are more wear-resistant but may require special handling during fabrication.

Processing and Machining

Ensure the plate can be easily cut, drilled, or welded to meet your specific design requirements.

Cost vs. Performance

Consider the total cost, including initial investment and maintenance savings. Wear resistant steel plates often pay off through reduced downtime and longer service life.

Table: Comparison of Wear Resistant Steel Plate Grades

| Grade | Hardness (HBW) | Impact Toughness | Typical Applications |

|---|---|---|---|

| AR400 | 360–440 | High | Construction equipment, dump truck liners |

| AR500 | 460–540 | Moderate | Mining tools, crushing machines |

| AR600 | 570–650 | Lower | Conveyor belts, severe wear environments |

How to Evaluate the Best Wear Resistant Steel Plate

Testing and Certification

- Check hardness using Brinell or Rockwell tests.

- Verify toughness, especially for applications involving impact.

Manufacturer Reputation

Choose a trusted supplier with proven quality standards and certifications.

Environmental Considerations

For corrosive environments, opt for plates with additional coatings or alloys to prevent rust.

Benefits of Wear Resistant Steel Plates

Enhanced Equipment Lifespan

These plates minimize wear and tear, extending the life of machinery.

Reduced Maintenance Costs

Fewer replacements and repairs result in lower long-term expenses.

Improved Efficiency

Durable machinery operates more smoothly, boosting productivity.

Versatile Applications

Wear resistant steel plates are used across multiple industries, including construction, mining, and agriculture.

Conclusion

Choosing the right wear resistant steel plate is a critical decision that impacts the efficiency and longevity of machinery. By understanding the material’s properties, applications, and benefits, you can select a plate that meets your operational needs while optimizing cost and performance.

Partnering with a reputable supplier ensures consistent quality and reliable support, making it easier to maximize the value of your investment in wear resistant steel plates.

FAQ

What is a wear resistant steel plate?

A wear resistant steel plate is a high-strength material designed to resist abrasion and extend the life of machinery in harsh environments.

Can wear resistant steel plates be welded?

Yes, they can be welded, but some grades may require specific techniques or pre-heating.

What industries use wear resistant steel plates?

Industries like mining, construction, agriculture, and transportation heavily rely on these plates.

How do I ensure the quality of a wear resistant steel plate?

Work with a reputable supplier and check certifications for hardness and toughness.

Are wear resistant steel plates corrosion-resistant?

Standard plates are not corrosion-resistant, but coatings or alloys can improve rust resistance.

Can wear resistant steel plates be customized?

Yes, they can be cut, bent, and machined to meet specific requirements.

Is it worth investing in wear resistant steel plates?

Yes, the durability and reduced maintenance costs often outweigh the initial investment, making them a cost-effective choice.