Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61565500692293

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

Galvanized steel sheets, often simply referred to as galvanized sheets, are a versatile and widely used material in various industries. This type of steel is created by applying a protective zinc coating to sheet steel, enhancing its corrosion resistance and durability. In this blog post, we will delve into the properties, applications, and benefits of galvanized sheets, providing valuable insights for engineers, manufacturers, and anyone interested in understanding this essential material.

What are Galvanized Sheets?

Galvanized sheets are steel sheets coated with a layer of zinc to protect them from corrosion. The galvanization process involves dipping the steel in molten zinc, which forms a protective layer that bonds with the steel. This process ensures that galvanized sheets withstand environmental elements such as moisture, extreme temperatures, and exposure to chemicals, which can all lead to rust and deterioration in non-galvanized metals.

In industrial settings, galvanized sheets offer high durability and versatility. Their protective coating is suitable for both outdoor and indoor use, providing long-lasting performance that minimizes maintenance and replacement costs.

Types of Galvanized Sheets

Galvanized sheets are available in different types, each with its own set of properties and ideal applications.

Hot-Dip Galvanized Sheets

- Description: These sheets are coated with zinc by passing them through a bath of molten zinc, providing a thick and robust coating.

- Applications: Ideal for outdoor applications, construction, and automotive industries due to their high corrosion resistance.

Electrolytic Galvanized Sheets

- Description: The zinc coating is applied through an electrochemical process, resulting in a smoother and more uniform finish.

- Applications: Commonly used in industries where a high-quality finish is required, such as in appliances and consumer goods.

Alloy-Coated Galvanized Sheets

- Description: These sheets have a coating of zinc-iron alloy, which provides better corrosion resistance and improved adhesion of paint and other coatings.

- Applications: Suitable for applications where superior corrosion resistance and paint adhesion are needed.

Cold-Rolled Galvanized Sheets

- Description: These sheets are made by cold-rolling steel that has been galvanized, resulting in a smoother surface and tighter tolerances.

- Applications: Used in precision applications where a smooth surface and close dimensional tolerances are required.

Comparison of Galvanized Steel Coatings

| Feature | Hot-dip Galvanized | Electrogalvanized | Zinc-Aluminum Alloys |

|---|---|---|---|

| Coating Thickness | Thick | Thin | Moderate |

| Corrosion Resistance | Excellent | Good | Very good |

| Paintability | Good | Excellent | Excellent |

| Cost | Moderate | Low | Moderate |

Advantages of Galvanized Sheets for Industrial Applications

There are many advantages to using galvanized sheets in industrial applications:

Corrosion Resistance

One of the primary reasons for using galvanized sheets is their resistance to corrosion. The zinc coating acts as a barrier, preventing rust and ensuring the longevity of the metal in harsh environments, such as those exposed to moisture, saltwater, or chemicals.

Cost-Effectiveness

Galvanized sheets are more affordable compared to stainless steel but still offer a high level of protection and durability. They’re often chosen for applications where large quantities of material are needed without compromising quality.

Durability and Strength

Galvanized sheets are known for their strength and durability. The galvanization process enhances the structural integrity of steel, making it suitable for heavy-duty applications. They can bear considerable loads and pressures, which is especially important in construction and infrastructure.

Versatility in Applications

From agricultural buildings to automotive parts, galvanized sheets are used across multiple industries. Their versatility makes them ideal for various applications where different shapes and sizes of materials are required.

Applications of Galvanized Sheets in Industrial Settings

Galvanized sheets are used in a wide range of industrial applications due to their strength, durability, and resistance to corrosion.

Construction Industry

- Applications: Roofing, cladding, structural beams, and components for bridges and buildings.

Automotive Industry

- Applications: Car bodies, chassis, exhaust systems, and other parts that require corrosion resistance.

Agricultural Industry

- Applications: Fencing, animal traps, gates, and other structures that are exposed to the elements.

Manufacturing and Industrial Equipment

- Applications: Industrial equipment, machinery parts, tanks, and conveyors that need to withstand harsh conditions.

HVAC and Ventilation Systems

- Applications: Ductwork, ventilation systems, and air handling units that are resistant to moisture and other environmental factors.

Renewable Energy

- Applications: Wind turbines, solar panel structures, and other components that are exposed to outdoor conditions.

Maintenance Tips for Galvanized Sheets

To ensure the longevity of galvanized sheets in industrial applications, follow these maintenance tips:

Regular Inspections: Examine the galvanized sheets carefully for any indications of damage, such as chipping, rust, or any other imperfections that may be present on their surface. It is essential to check all areas thoroughly to ensure that no issues are overlooked. If you notice that any part of the protective coating has been compromised or damaged in any way, it is advisable to take action to repair it as soon as possible. Addressing these issues promptly is crucial in order to prevent further corrosion and deterioration of the material over time. Taking preventive measures today can save you from more significant problems down the line.

Cleaning: It is important to clean the surface on a regular basis to effectively remove any dirt and contaminants that may have built up over time. These accumulated substances can compromise the integrity of the protective zinc coating, which is essential for maintaining the surface’s durability and resistance to corrosion.

Avoid Harsh Chemicals: While galvanized sheets are resistant to many elements, using harsh chemicals can wear down the protective layer. Use mild detergents if needed and rinse thoroughly after cleaning.

Protect from Physical Damage: If galvanized sheets are subject to high impact or abrasive environments, consider adding an additional protective layer or using thicker gauge sheets.

Conclusion

Galvanized sheets are an invaluable component of modern industrial applications, offering an ideal blend of durability, affordability, and corrosion resistance. By understanding the various types available and their specific advantages, industries can make informed choices that lead to better performance and cost savings. Investing in the right type of galvanized sheet for your application and following proper maintenance practices will ensure a long-lasting, reliable solution for your material needs.

FAQ

What are the main benefits of using galvanized sheets in industrial applications?

Galvanized sheets offer durability, corrosion resistance, cost-effectiveness, and versatility, making them an ideal choice for a wide range of industrial applications.

Which type of galvanized sheet is best for coastal environments?

Galvalume sheets, which are coated with aluminum, zinc, and silicon, are particularly suitable for coastal environments due to their resistance to saltwater corrosion.

How does electro-galvanizing differ from hot-dipping?

Electro-galvanizing involves coating the sheet through an electrochemical process, resulting in a thinner, smoother coating, whereas hot-dipping produces a thicker, more durable coating.

Are galvanized sheets suitable for use in the automotive industry?

Yes, electro-galvanized sheets are commonly used in the automotive industry due to their smooth finish, which is ideal for car body parts.

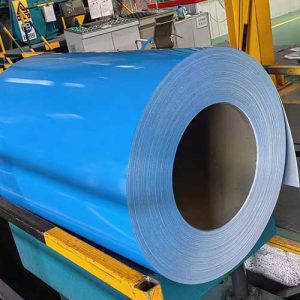

Can galvanized sheets be painted for aesthetic purposes?

Yes, pre-painted galvanized sheets offer both aesthetic appeal and functional benefits, commonly used in architectural and exterior design applications.