Introduction

What are Rolls of Galvanized Sheet Metal?

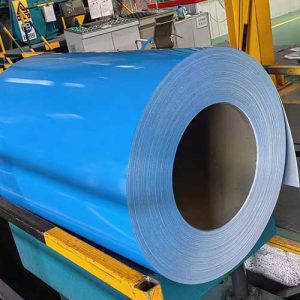

Rolls of galvanized sheet metal are steel coils that have been coated with a protective layer of zinc. This zinc coating provides excellent corrosion resistance, making galvanized steel a popular choice for a wide range of applications. The process of galvanizing involves immersing the steel in a molten zinc bath, resulting in a durable and adherent zinc coating.

Why is Galvanized Sheet Metal so Versatile?

The versatility of galvanized sheet metal can be attributed to its combination of properties. The zinc coating not only protects the underlying steel from corrosion but also enhances its paintability and weldability. Additionally, galvanized steel is relatively lightweight and easy to form, making it suitable for a variety of manufacturing processes.

The Galvanization Process

The galvanization process typically involves the following steps:

Cleaning: The steel coils are cleaned to remove any impurities that could interfere with the bonding of the zinc coating.

Fluxing: A flux is applied to the steel surface to promote the adhesion of the zinc.

Galvanizing: The steel coils are passed through a molten zinc bath, where the zinc adheres to the steel surface.

Cooling: The galvanized steel coils are cooled to solidify the zinc coating.

Chemical Composition of Galvanized Steel

While the base material of galvanized steel is typically carbon steel, the specific chemical composition can vary depending on the intended application. The addition of alloying elements like chromium, nickel, and molybdenum can enhance the properties of the steel, such as its strength, toughness, and corrosion resistance.

Applications of Galvanized Sheet Metal

Galvanized sheet metal finds extensive use in various industries due to its versatility and cost-effectiveness. Some of the most common applications include:

- Construction: Roofing, siding, gutters, and downspouts. Galvanized steel’s durability and corrosion resistance make it an ideal choice for exterior applications.

- Automotive: Body panels, underbody components, and exhaust systems. The lightweight nature of galvanized steel and its resistance to rust contribute to its popularity in the automotive industry.

- Appliances: White goods, such as refrigerators, washing machines, and ovens. Galvanized steel provides a durable and hygienic surface for these appliances.

- Manufacturing: Ductwork, storage tanks, and other industrial equipment. The corrosion resistance and formability of galvanized steel make it well-suited for these applications.

Table: Common Applications of Galvanized Sheet Metal

| Industry | Applications |

|---|---|

| Construction | Roofing, siding, gutters, downspouts, fencing, and decking |

| Automotive | Body panels, underbody components, exhaust systems, and fuel tanks |

| Appliances | White goods, such as refrigerators, washing machines, and ovens |

| Manufacturing | Ductwork, storage tanks, and other industrial equipment |

Advantages of Galvanized Sheet Metal

- Corrosion resistance: The zinc coating provides excellent protection against rust and corrosion.

- Durability: Galvanized steel is highly durable and can withstand harsh weather conditions.

- Versatility: It can be easily formed, welded, and painted.

- Cost-effective: Galvanized steel is a cost-effective solution for many applications.

- Sustainability: Galvanized steel is recyclable and can contribute to a more sustainable future.

Conclusion

Rolls of galvanized sheet metal are a versatile and durable material that offers numerous advantages. Its combination of corrosion resistance, strength, and formability makes it an ideal choice for a wide range of applications. Whether it’s used in construction, automotive, or manufacturing, galvanized steel continues to be a popular choice for engineers and designers alike.

FAQ

What are the common applications of rolls of galvanized sheet metal?

Rolls of galvanized sheet metal are commonly used in construction, automotive manufacturing, HVAC systems, roofing, and outdoor structures due to their corrosion resistance and durability.

How are rolls of galvanized sheet metal used in roofing?

They are used for roofing sheets, gutters, and downspouts because the galvanized coating protects against rust, making them ideal for withstanding harsh weather conditions.

Can rolls of galvanized sheet metal be used in HVAC systems?

Yes, rolls of galvanized sheet metal are widely used for ductwork in HVAC systems due to their ability to resist moisture and corrosion, ensuring long-lasting air distribution.

Are rolls of galvanized sheet metal suitable for outdoor structures?

Absolutely. These metal sheets are perfect for fences, sheds, and other outdoor structures, offering both structural integrity and resistance to rust in outdoor environments.

Why are rolls of galvanized sheet metal popular in automotive applications?

They are used in car bodies, undercarriages, and other components because their corrosion resistance extends the lifespan of vehicles, even in harsh driving conditions.