Table of Contents

Introduction

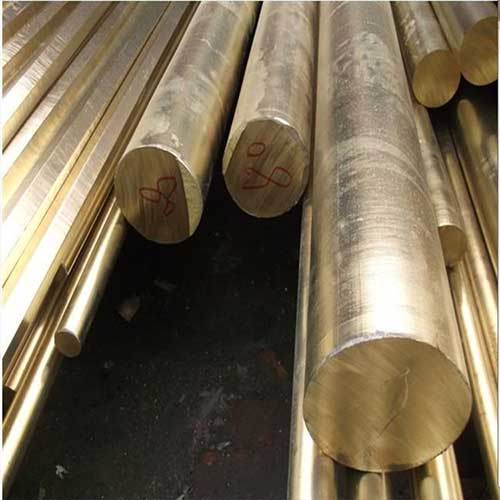

Solid copper rods are cylindrical pieces of copper that are manufactured to be used in various industrial, electrical, and construction applications. These rods are highly sought after because of their ability to conduct electricity efficiently, resist corrosion, and endure harsh environmental conditions. From small electrical components to large industrial systems, solid copper rods can be found in a multitude of settings.

In this comprehensive guide, we will explore the key properties, types, and uses of solid copper rods, providing you with a complete understanding of why these rods are a go-to material in many industries.

The Properties of Solid Copper Rod

Electrical Conductivity

One of the most notable properties of solid copper rod is its excellent electrical conductivity. Copper is second only to silver in terms of its ability to conduct electricity, making it a preferred choice in electrical wiring and components. The use of solid copper rod in grounding, electrical connectors, and busbars is primarily due to this high conductivity, ensuring efficient transmission of electricity with minimal energy loss.

Corrosion Resistance

Solid copper rod offers superior resistance to corrosion, particularly in wet and humid environments. This makes it ideal for outdoor applications such as grounding rods in electrical installations or as components in marine and construction environments. Copper’s natural oxide layer provides a protective barrier that prevents further oxidation and deterioration, giving solid copper rods a long lifespan.

Malleability and Strength

Solid copper rods are both strong and malleable, making them easy to shape without losing their structural integrity. This allows for customization in manufacturing and installation processes, where copper rods can be bent, twisted, or otherwise formed to fit specific requirements without breaking.

Common Uses of Solid Copper Rod

Electrical Applications

One of the most common uses of solid copper rod is in electrical systems, where its excellent conductivity is vital. Copper rods are used in:

- Grounding systems: Solid copper rods are often installed in the ground to dissipate electrical currents safely into the earth.

- Electrical connectors: Copper rods are used to manufacture connectors that ensure a reliable connection between different electrical components.

- Busbars: In high-power electrical installations, solid copper rods serve as busbars, which conduct large amounts of electricity across power distribution panels.

Construction and Architecture

In construction, solid copper rods are used as part of structural components and in building facades for their durability and resistance to weathering. Copper’s aesthetic appeal and longevity make it a favored material in decorative elements, roofing, and lightning protection systems.

Manufacturing and Industrial Use

Solid copper rod plays an essential role in the manufacturing of components for various industries, including automotive, aerospace, and machinery. It is used to create bearings, gears, and various machine parts due to its strength and resistance to wear.

Table: Common Specifications for Solid Copper Rod

| Specification | Details |

|---|---|

| Diameter Range | 2mm to 150mm |

| Length | Customizable (standard 3m or 6m) |

| Conductivity | 100% IACS (International Annealed Copper Standard) |

| Temper | Hard, soft, and half-hard |

| Tensile Strength | Varies (up to 400 MPa depending on temper) |

| Corrosion Resistance | Excellent, especially in humid environments |

| Applications | Electrical, construction, manufacturing, plumbing |

This table provides an overview of common specifications for solid copper rods, helping buyers to understand the variety of dimensions and properties available for different applications.

Advantages of Using Solid Copper Rod

Durability and Longevity

Solid copper rod is known for its durability and long lifespan, even in harsh environments. Its resistance to corrosion and wear means that it requires little maintenance, making it a cost-effective choice over time. This is particularly important in outdoor and industrial settings where materials are exposed to the elements or harsh working conditions.

Versatility in Application

The versatility of solid copper rod makes it an indispensable material across many industries. Whether it’s being used in large industrial machines or small electrical connectors, copper rods can be shaped, cut, and adapted to meet specific project needs. This flexibility makes it easy for manufacturers to produce components that adhere to exact specifications.

High Recyclability

Copper is one of the most recycled metals in the world. Using solid copper rods in your projects not only ensures excellent performance but also aligns with environmental sustainability goals. Copper retains its properties even after being recycled, making it an eco-friendly choice for those looking to minimize waste.

Selecting the Right Solid Copper Rod for Your Project

Understanding the Different Grades

Copper rods come in various grades depending on the purity and specific alloy used. The most common types of copper used in solid copper rods are:

- Oxygen-Free Copper (OFC): Highly pure copper with excellent conductivity and no oxygen content, ideal for sensitive electrical applications.

- Electrolytic Tough Pitch (ETP): This is the most common type of copper, used in general electrical and industrial applications due to its balance of conductivity and mechanical strength.

- Deoxidized Copper: Contains a small amount of phosphorus, which increases its corrosion resistance, particularly in applications like plumbing or marine environments.

Choosing the Right Size and Temper

The size of the solid copper rod is determined by the needs of the project, with diameters ranging from a few millimeters to several inches. The temper of the copper—whether it is hard, half-hard, or soft—will also impact its suitability for different applications. Softer tempers are easier to shape and bend, while harder tempers provide more strength and rigidity.

Conclusion

Solid copper rod remains one of the most versatile and reliable materials available for industrial, electrical, and construction applications. Its high conductivity, corrosion resistance, and malleability make it a preferred material for professionals seeking long-lasting and efficient solutions. Whether you’re designing electrical systems, building infrastructure, or manufacturing durable components, solid copper rods offer unparalleled performance.

By understanding the various types of copper rods, their properties, and their applications, you can select the best product for your project’s needs. With its combination of strength, flexibility, and sustainability, copper rod continues to be an indispensable material in modern industries.

FAQ

What are the primary uses of solid copper rod?

Copper rods are primarily used in electrical applications such as grounding systems, connectors, and busbars. They are also used in construction, manufacturing, and decorative architectural elements due to their strength and corrosion resistance.

How do I choose the right copper rod for my project?

To choose the right copper rod, consider the diameter, length, and temper based on the specific needs of your project. Also, be sure to select the appropriate copper grade, whether it’s oxygen-free for sensitive electrical applications or deoxidized for better corrosion resistance.

Can copper rod be recycled?

Yes, copper rods are fully recyclable without losing their properties. Copper is one of the most sustainable materials, as it retains its conductivity, strength, and corrosion resistance even after recycling.

What is the difference between oxygen-free copper and electrolytic tough pitch copper?

Oxygen-free copper has no oxygen content and offers higher conductivity, making it ideal for high-performance electrical applications. Electrolytic tough pitch (ETP) copper contains a small amount of oxygen but offers a good balance of conductivity and mechanical strength, making it suitable for general industrial and electrical uses.

How long do copper rods last in outdoor applications?

Copper rods are highly durable and resistant to corrosion, particularly in outdoor and humid environments. They can last for decades, making them a cost-effective solution for long-term use in grounding systems, marine applications, and construction projects.